Rapid Tooling

Rapid tooling including prototype mold, RIM, ABS mold and Aluminum mold ,which is good for low volume production from 1k to 10K. This process is the best choice if you have a project with the small numbers.

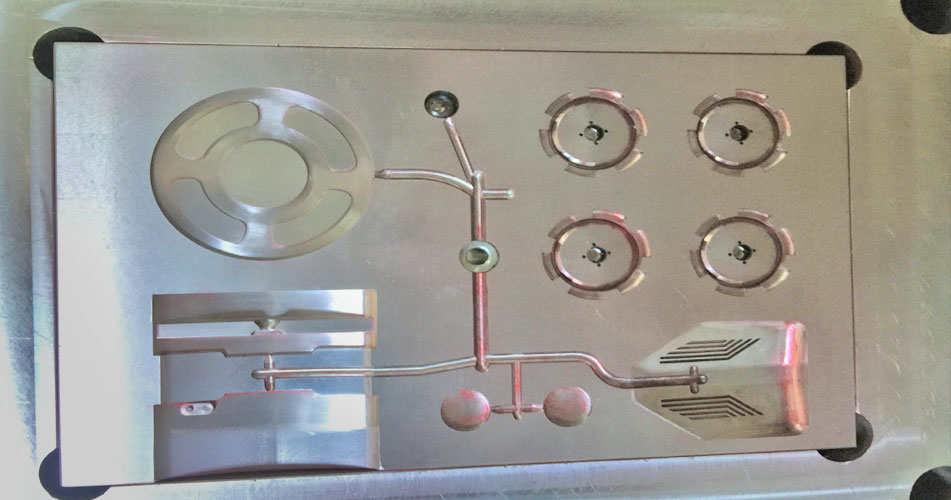

Prototype mold is also called the injection mold.The tool life of prototype mold is shorter than mass production mold, which means the molds will be reduced in some machining process.For example,more than one cavity can share with a universal mold base. Also, we will choose different grades of steel material according to your products quantity, quality and surface finishing requirement. This is the best way for shortening processing time and saving the cost of the tool.

Reaction injection molding and injection molding have almost the same name, so even experienced engineers and designers might think they are same process. But “Reaction” signals a big difference – unlike injection molding, RIM techniques utilize low-viscosity liquid polymers in thermoset – not thermoplastic – processes. Through a variety of chemical reactions, these polymers expand, thicken and harden only after they’re injected into the heated mold, accommodating much more intricate designs than ordinary injection molding. Raw materials and molding techniques can be selected and even customized to precisely deliver desired weight, strength, density and hardness characteristics. The result is large polyurethane parts with much lighter weight than those created by more commonplace processes.

Making an ABS mold by CNC or 3d printing process is usually for low volume silicone rubber parts and over-molding parts.

Making an Aluminium mold by CNC machining is usually used for making low volume interior structural parts from 1K to 2K without surface requirement’s plastic component.