What is SLA and SLS?

SLA (stereolithography) is the first of the additive manufacturing processes collectively known as “3D printing”. A special type of liquid plastic is used that reacts with ultraviolet (UV) light to form a solid. An object is created by slowly curing one layer at a time using a programmable UV light source.

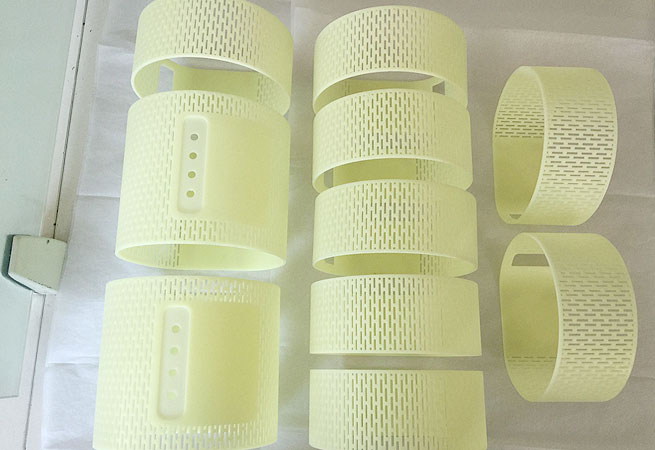

SLS (stereo laser sintering) is also a method for making rapid plastic prototypes, but in this case the raw material is a fine powder. A programmed laser is used to fuse the powder into a solid one layer at a time to create the finished product. Objects are created on a build platform, which is carefully controlled by a computer to move down the thickness of one layer with each successive addition of powder.

Advantages of 3d printing

There is no other method compares to 3D printing rapid prototyping when it comes to getting prototypes fast and at a low cost . If you need a preliminary sample to test for form, fit or simply aesthetics, 3D printing rapid prototyping is the best option. The complex geometries enabled by the 3D printing process let you create intricate parts to accurately gauge manufacturability and other considerations before making the decision to move to more functional testing.

Rapid development

No material waste produced

Low cost

Casting and Molding Pattern

Good at small and complex geometries parts

Rapid Tooling Patterns for Plastic, Metal Parts

*3D printing Services File Formats Supported: STL, IGES, IGS, STEP, STP, X_T, Take a look at work process.

Our one stop shop prototyping services include Rapid Prototyping, CNC Machining, SLA/SLS 3D printing, Low volume production, rapid tooling, sheet metal, Injection molding and Die casting.