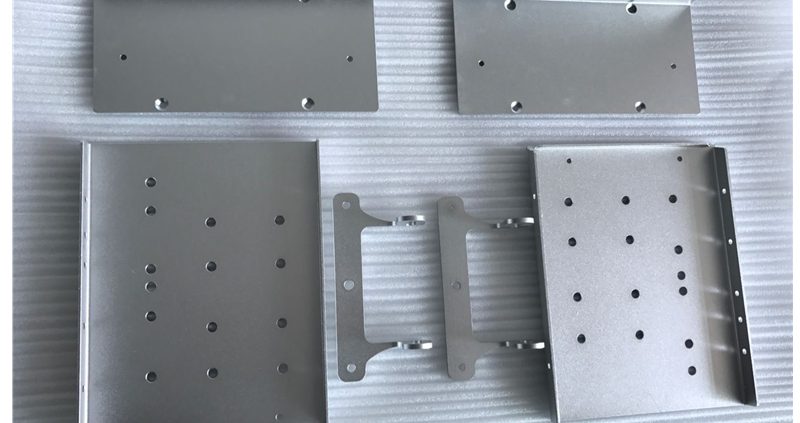

Sheet Metal Working

Sheet Metal Working

With the characteristics of light weight, high strength, conductivity, low cost and good mass production performance,metal plate is a technology that has been widely used in electronic and electrical appliances, communication, automobile industry, medical devices and other fields. For example,it is an essential part in computer chassis, mobile phone,and so on.

The material of metal plate widely be used in electronic enterprises is SPCC,SECC,SGCC,SUS301,SUS304,etc.There are three main types of sheet metal processing: blanking, bending and stretching. Different processing technologies have different requirements for sheet metal. The selection of sheet metal also need be considered according to the shape of the product and processing technology.The following is the impact of materials on sheet metal processing technology.

a,The influence of materials on punching process.

Punching requires that the plate material should have enough plasticity to ensure the plate will not crack during machining.The soft materials such as pure aluminum,antirust aluminum, brass, red copper and mild steel have good punching performance,which can be blanked to the parts that have a smooth section and a small inclination.The quality of the hard materials is not good after punching,such as high-carbon steel,stainless steel,duralumin and ultralumin, the section unevenness is large, especially for the thick plate material.

b,, The influence of materials on bending process.

The plate materials to be bent should have sufficient plasticity and low yield limit.The plate with high plasticity is not easy to crack when bending. The plate with low yield limit and low elastic modulus has small rebound deformation after bending, and it is easy to obtain the bending shape with accurate size. Materials with good plasticity such as low carbon steel, brass and aluminum with carbon content less than 0.2% are easy to bend and form; Materials with high brittleness, such as phosphor bronze (qsn6.5 ~ 2.5), spring steel (65Mn), hard aluminum, superhard aluminum, etc., must have a large relative bending radius (R / T) during bending, otherwise they are easy to crack during bending.

c,The influence of materials on tensile process.

Sheet metal stretching, especially deep stretching, is a difficult kind of sheet metal processing technology. It not only requires the stretching depth to be as small as possible, the shape to be as simple and smooth as possible, but also requires the material to have good plasticity. Otherwise, it is very easy to cause overall distortion, local wrinkling and even tensile cracking of the parts.