Metal 3D printing

Metal 3D printing

What is metal 3D printing?

Metal 3D printing is a process of manufacturing three-dimensional parts based on digital files. It usually uses layer-by-layer processing or solidification of thin metal powder materials to make complete parts. This technology can produce complex parts that cannot be achieved by traditional techniques such as die casting, forging and CNC machining.

The advantage of metal 3D printing;

3D printing has many advantage, especially if you know how to optimize product designs to take advantage of them. Advantage include:

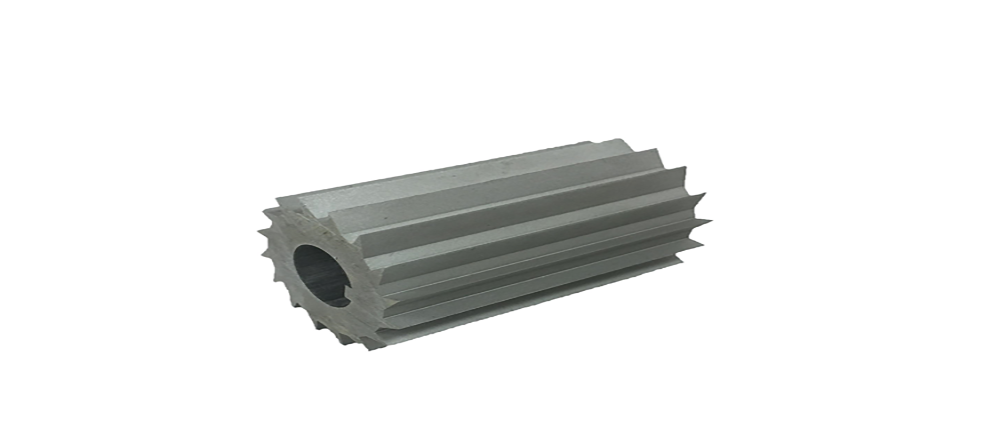

Metal 3D printed parts are completely dense, containing complex geometric shapes and precise internal features that cannot be manufactured using traditional machining alone.

The design can be done quickly with minimal material waste while maximizing strength.

Conformal cooling channels greatly improve performance and resistance to thermal stress, making it ideal for aerospace and automotive applications

Multiple identical parts can be make on one machine at the same time, which greatly improves production efficiency.

Metal 3D printing process:

First, a 3D CAD file must be provided for the design. In order to get the best results, our engineers must check your CAD drawing files in advance and optimize the design if necessary. This can include optimizing the build direction and adding support structures to areas where gravity may cause the features to distort during printing. These support will be removed later

We then used specialized software to cut the drawing into multiple cross-sectional layers, with each layer representing a 20-60μm thickness of the final shape.Finally, we upload the slice file to the machine to be printed.Using the Renishaw AM250, an advanced metal 3D printer for rapid prototyping and manufacturing.

Metal 3D printing tolerances:

The general tolerance for metal 3D printing is +/- 0.5mm. However, it depends significantly on the geometry of the part being printed. See more guidelines to follow when designing metal 3D printing.

Metal 3D printing materials:

Currently, we provide 3D metal printing of titanium, stainless steel, maraging steel and aluminum. Each material has unique advantages related to mechanical properties, weight, corrosion resistance, etc. Economic costs also need to be considered, so our engineers are happy to advise you on the best materials for your application and budget.

If you need to make metal parts quickly,E-make will be your best choice.

[/av_textblock]