Excellent 5-Axis CNC Machining Services

Excellent 5-Axis CNC Machining Services

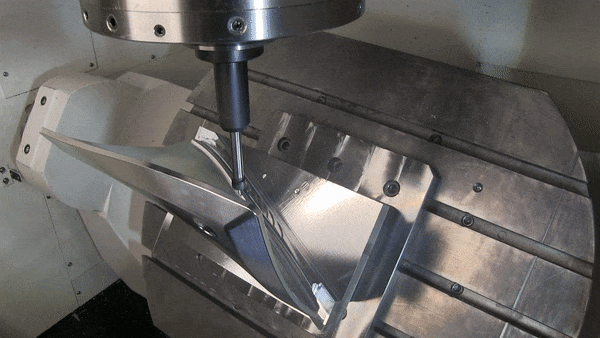

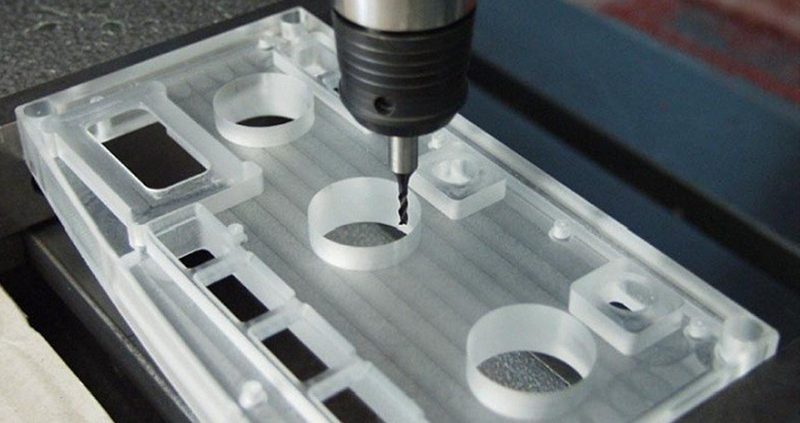

First we need to recognize what is the 5-axis CNC machining? 5-axis CNC machining is making use of computer system mathematical control (CNC) to move a tool or component all at once along five axes. The cutting tool actions continually along each axis to ensure that the pointer is always perpendicular to the component. This procedure permits you to equipment all sort of complicated parts.

Benefits of 5-axis CNC machining

Solitary Configuration: 3-axis makers call for several setups, which can cause wrong alignment, greater expenses, and also other errors. With 5-axis CNC machining, you can maker complex shapes in a single configuration, raising performance, conserving time, reducing expenses as well as avoiding operator error.

Shorter devices: 5-axis CNC machining permits you to utilize much shorter devices because you can decrease the head and place the device appropriately. This helps achieve greater cutting speeds without putting excessive stress on the tool. Much shorter cutting tools likewise minimize tool vibration, which can cause dental caries as well as cores. You’ll see a better surface finish as a result of much less vibration on the 5-axis device.

Facility Parts: 5-axis CNC machining process permits you to equipment complicated components that would otherwise call for casting. If you have a low-volume production or prototype, you’ll have the ability to equipment the part in a couple of weeks, as opposed to waiting months for casting.

Enhanced tool life: You can keep continuous chip tons and also optimal cutting setting to boost tool cycle time and life.

Exploration: 5-axis CNC machining gives the capability to drill a collection of holes with various compound angles in time. This conserves a lot of time– if you are using a 3-axis equipment, you will certainly need to utilize different settings for each and every face.

Accident avoidance: the capacity to tilt the table or cutting device to avoid crash with the tool owner

If you have a new item that need to make a prototype to design inspection and check the architectural design. Please do not hesitate to speak to us. As a prototype manufacturing facility for 20 years.We can make any product.