What You Should Know Before CNC Production Machining?

What You Should Know Before CNC Production Machining?

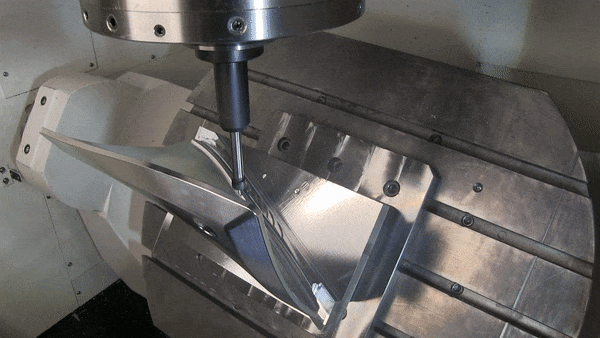

Everything before this subject is prep work. CNC Machining is where the rubber meets the road. All the steps of CNC before machining are just planning for the machining stage of the job. An easy interpretation of machining is eliminating material. You eliminate material in various means to come up with the component or piece.

CNC Machining can be carried out on countless types of product. As an example, wood, steel, light weight aluminum, and also rock. Machining normally has greater tolerances connected with it. When machining, you are attempting to do something much more accurate.

In machining, we use some sort of tool. This device could be a grinder, drill bit, end mill, router little bit or various other device. There are unlimited variations of tools. CNC Tooling usually costs a reasonable amount of cash. When you purchase your tooling though, you can use it over and over up until it wears. If you have a big range of various tools, you will be able to do a big selection of machining kinds.

Right here is a listing of typical tooling utilized in CNC Machines:

Drill little bits

End mills

Plasma cutter

Dovetail cutter

Fly cutter

If you wish to take a look at different sorts of CNC tooling, go to one of these resources on the Internet:

Enco

Travers

McMasters-Carr

Grainger

Browse a few of these suppliers’ catalogs and you will certainly get a suggestion concerning the boundless designs of tooling.

CNC is used in the machining procedure. Normally, you can get better accuracy, quicker production, as well as general effectiveness when making use of CNC machining. This is why it has ended up being so popular. In the past, CNC machining was very costly. In time, it has come to be somewhat cost-effective as well as currently individuals do it as a pastime. I am presuming that is why you are right here.

Right here are a few various types of CNC devices that execute different machining procedures:

Milling machines

Wood routers

Plasma cutters

Foam cutters

Press brakes

Turrets

Cutoff saws

People have actually effectively used CNC to practically any kind of type of motion control. The only thing that will restrict you is your creative imagination.

If you have a new item that need to make a prototype to design inspection and check the architectural design.Please do not hesitate to speak to us. As a prototype manufacturing facility for 20 years. We can make any product.