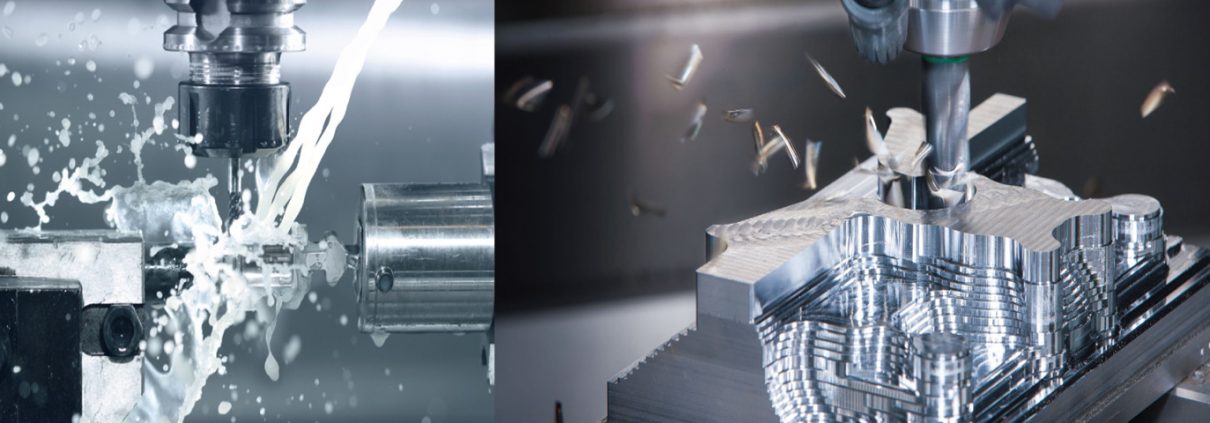

CNC Milling Machining Technology

CNC Milling Machining Technology

The process of CNC machining have much impact on the quality of the product that produced by CNC machining,and the CNC machine play an important role in the CNC machining ptocess.

Comparing with the normal machine,the CNC machine have some characteristics as below:

A,It has strong adaptability to the processing object, adapt to the characteristics of mold and other single-piece production,and provides a suitable processing method for mold manufacturing;

B,It can be used in prototype production or small batch production.

C,The parts made by CNC milling have high precision and stable processing quality.Generally,for metal parts,the precision can meet 0.01-0.1mm.When processing the same batch of parts on the same machine tool and under the same processing conditions, using the same tool and processing program, the tool path is exactly the same, so the consistency of parts is good and the quality is stable.

D,The tool of CNC machine can move in multiple coordinates and process parts with complex shapes.

E,If customer need to change the shape or structure of the machined parts, generally we only need to change the program,which can save production preparation time;

F,The CNC machine has high precision and high rigidity, so that we can choose our favorable processing material dosage,which are more productivity.

G,It is conducive to the modernization of production management. CNC machine tools use digital information and standard code to process and transmit information, and use computer control methods, which lays a foundation for the integration of computer-aided design, manufacturing and management

H,Processing parts on a CNC machine tool mainly depends on the processing program. It is different from an ordinary machine tool. It does not need to be manufactured, many molds and fixtures are replaced, and the machine tool does not need to be re-adjusted frequently. Therefore, the CNC machine tool is suitable for the occasions where the processed parts are frequently replaced, that is, it is suitable for the production of single-piece, small-batch products and the development of new products, thereby shortening the production preparation cycle and saving a lot of process equipment costs.

I,CNC machine require more higher quality requirements for operators and higher technical requirements for maintenance personnel;

E-make are professional in CNC milling machining years,if you have project need to make with metal,plastic,wood or Macro by CNC milling,please don’t hestate to contact us.