How dose CNC Machining work?

How dose CNC Machining work?

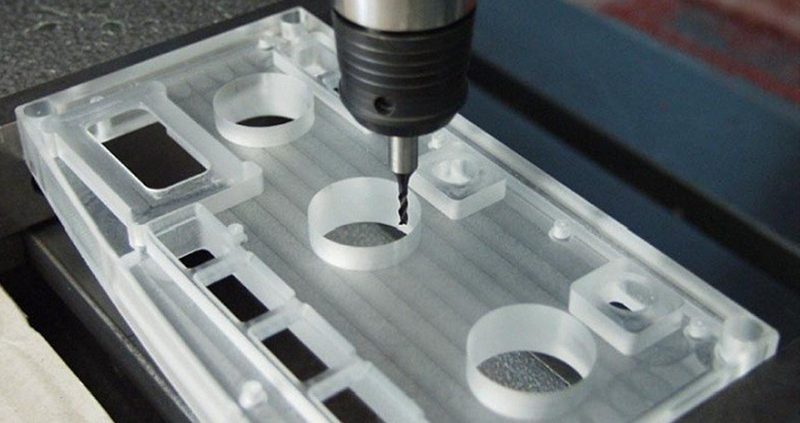

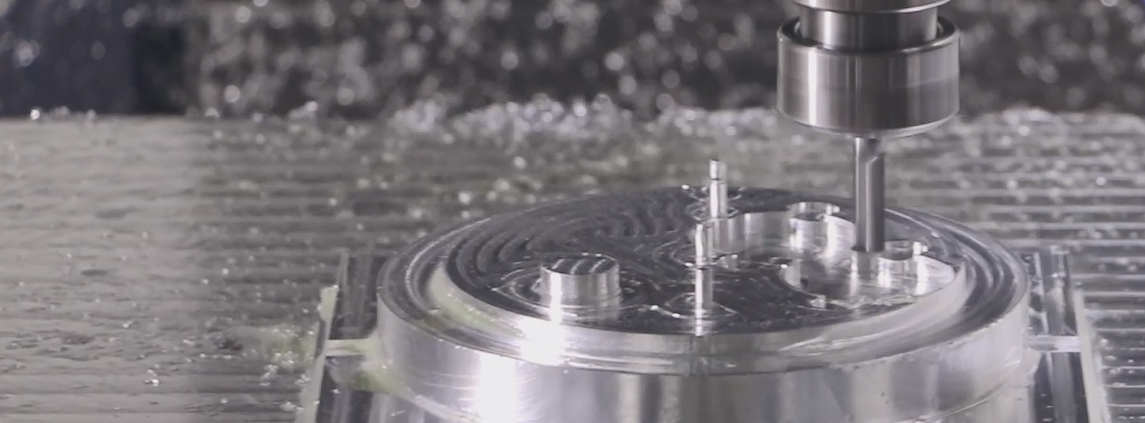

Whatever before this subject is preparation. CNC Machining is where the rubber satisfies the roadway. All the actions of CNC before machining are simply getting ready for the machining phase of the task. A simple definition of machining is getting rid of product. You get rid of product in numerous methods ahead up with the part or piece.

CNC Machining can be carried out on countless kinds of product. For instance, wood, steel, light weight aluminum, as well as rock. Machining normally has greater tolerances associated with it. When machining, you are attempting to do something more specific.

In machining, we use some sort of tool. This device could be a mill, drill little bit, end mill, router little bit or other device. There are infinite variants of tools. CNC Tooling normally costs a reasonable amount of money. Once you invest in your tooling though, you can use it repeatedly till it wears out. If you have a large range of different tools, you will have the ability to carry out a large variety of machining kinds.

Right here is a list of typical tooling utilized in CNC Machines:

Drill little bits

End mills

Plasma cutter

Dovetail cutter

Fly cutter

If you would like to check out various types of CNC tooling, most likely to among these resources on the net:

Enco

Travers

McMasters-Carr

Grainger

Browse a few of these providers’ directories and you will certainly obtain a suggestion concerning the infinite styles of tooling.

CNC is used in the machining process. Generally, you can improve accuracy, quicker production, and also total performances when utilizing CNC machining. This is why it has actually come to be so prominent. In the past, CNC machining was very expensive. Gradually, it has come to be somewhat affordable and also now individuals do it as a hobby. I am presuming that is why you are here.

Here are a couple of various kinds of CNC devices that execute numerous machining procedures:

Milling equipments

Timber routers

Plasma cutters

Foam cutters

Press brakes

Turrets

Cutoff saws

Individuals have successfully used CNC to essentially any type of sort of activity control. The only thing that will certainly limit you is your imagination.

The E-make group has more than three decades of combined experience in model machining, CNC manufacturing. If you require any help, please do not hesitate to contact us.