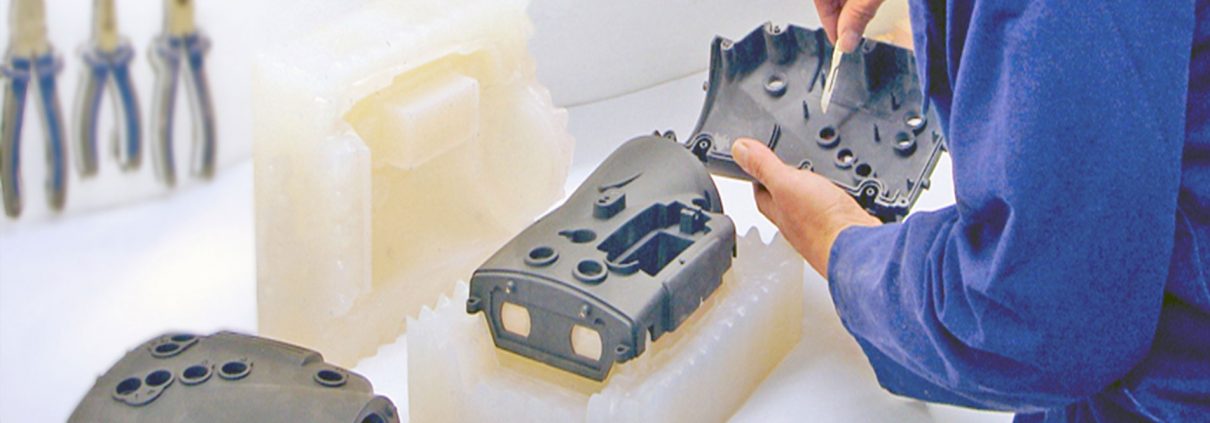

Vacuum casting ABS UL94 V0 prototype

Vacuum casting ABS UL94 V0 prototype

The vacuum casting greatly reduces the development cost, cycle and risk of the product. More than 20 pieces of the same product can be made using a silicone mold. This makes the vacuum mold become one of the commonly used prototype manufacturing methods in industrial production.

The vacuum mold refers to the use of the original prototype to make a silicone mold in a vacuum state, and use PU, transparent PU, POM-like, ABS materials for casting in a vacuum state,

So as to clone the same copy as the original prototype.

There are many materials for vacuum casting, and it can also be made of fireproof materials. Can withstand a high temperature of 180 degrees. So how do we produce fire-resistant ABS prototypes?

1,The first is to check the drawings to evaluate the production. Because the shrinkage rate of the vacuum casting is relatively large.In order to ensure the accuracy of the parts, the size of the parts needs to be enlarged according to the probability of shrinkage before production.

2,3D-Printed master mold.

3Make silicone mold.

4,Put the liquid fireproof ABS into the mold and take out the product after cooling.