Car rear light prototype manufacturing

Car rear light prototype manufacturing

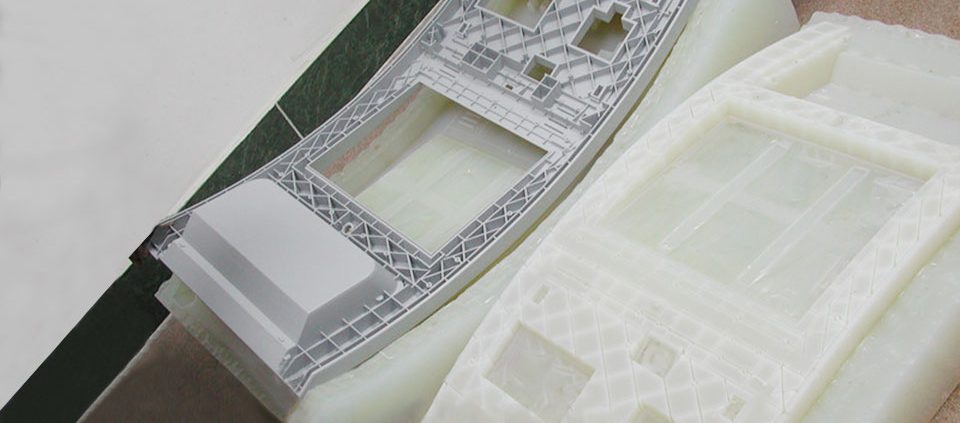

Name:car rear light prototype

Color:can custom any color according customer requirements.

Material:PC,TransparentPMMA,ABS,POM

Size:The dimensions of 3D drawings provided by customers shall prevail

Time:8days

Types:prototype of auto parts

Characteristics of prototype:

1,Clear lines,relying on imported equipment and unique process design, precision machining makes the line stripe path and outline more clear and smooth.

2,High efficient,strong strength.The company focuses on prototype processing for 12 years,we have accumulated a lot of relevant experience and talents,can efficiently meet customer requirements ,Meet customer requirements under the premise of faster order completion.

3,Higher precision, imported equipment, precision tolerance ±0.05mm.

4,Fast efficiency and short processing time.

Excellent talents, a wider range of processing size.

Advantage:

1,High quality and reasonable price

2,Machining, drawing or sample.

3,Can according 3D drawings and 2d drawings。

4,3D drawing file format :IGS/X-T/PRT/STP /STL is all available.

5,Custom samples and technical specifications are welcome。

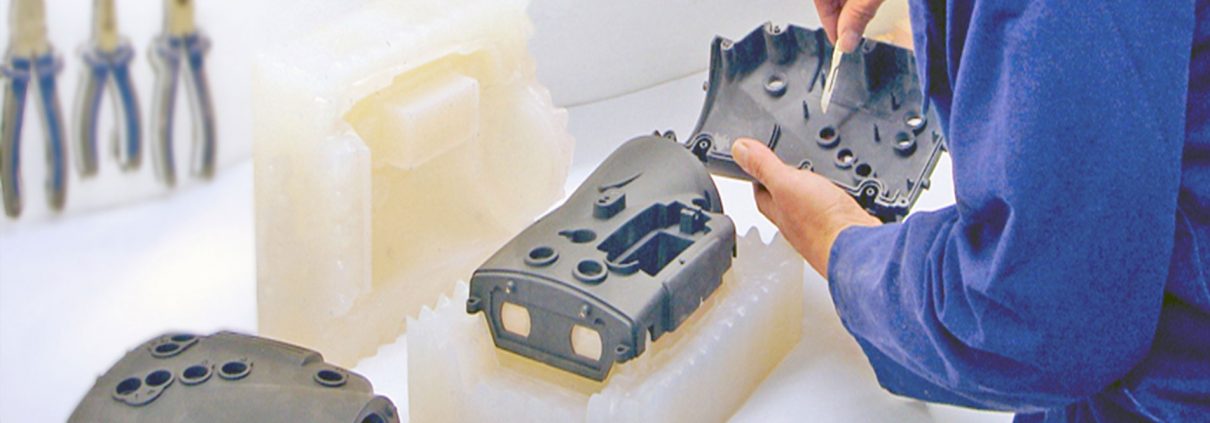

Automobile rear light hand plate model can be carried out:

1,CNC machining

2,polishing

3,painting

4, electroplating

5,assemble

E-make prototype advantages and strength characteristics:

1,Quote in 1 hour, delivery in 2 working days.

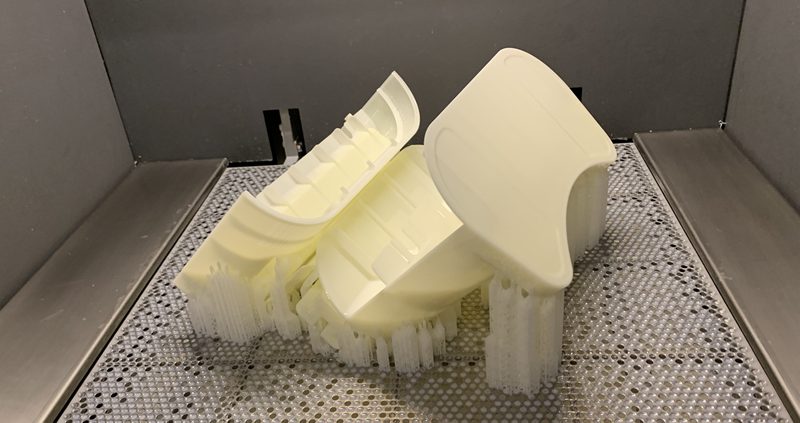

2,Our company has SLS and DLP from Germany, SLA rapid prototyping equipment from America, Stratasys 3D printer from America, metal powder 3D printer from America, and ProJet860 full-color 3D printing equipment from America. Taiwan imported CNC machining center 10 sets, vacuum casting, low pressure perfusion.

3,Prototype appearance can be spray paint, electroplating, wire drawing, screen printing.

4,We can make 3D printing prototype, plastic prototype, hardware prototypr, function prototype, appearance prototype, transparent prototype, high temperature resistant prototype, coffee machine prototype, kitchen appliance hand board, auto parts hand board and so on.

5,Packing: inner packaging: pearl cotton, transparent bag. Outer package: carton.

If you need do auto parts prototype,please feel free to contact us .

E-mail:amy@e-make.co