The processing of vacuum casting prototype

The processing of vacuum casting prototype

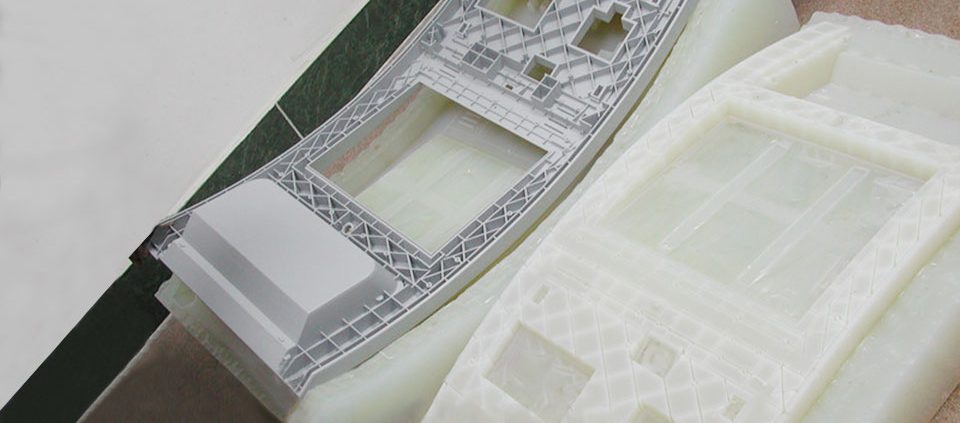

We usually use CNC maching to processing prototype ,but the CNC tooling is hard , can only process hard material.So if customer need to make rubber product ,we will not be able to use CNC machining .In that time ,we will use vacuum casting to process.vacuum casting is the best way to make rubber product in small quantity.So how vacuum casting to process a prototype?

1,programming.

2,make a mold.

3,Pour the liquid soft rubber material into the mold and take it out after cooling.

4,surface finish:

If those rubber product need to do color,there have two way to make color.one is painting after the product out of mold .Another is the color and the product out of mold together.This mean mix the color powder andrubber materials required by the customer into the mold, and take them out after cooling.

At this time, the product comes with its own color when it comes out of the mold. But the price will be more expensive than painting.

The surface of the vacuum casting product is smooth, and generally does not need manual processing. Which can save manual processing time.

If you have rubber products to make, please contact E-make. We are a rapid prototyping manufacturer in China, with over 10 years of experience in CNC,3D printing, vacuum casting and injection molding die-casting prototypes. We can quickly and cheaply produce high quality parts and prototype for you.