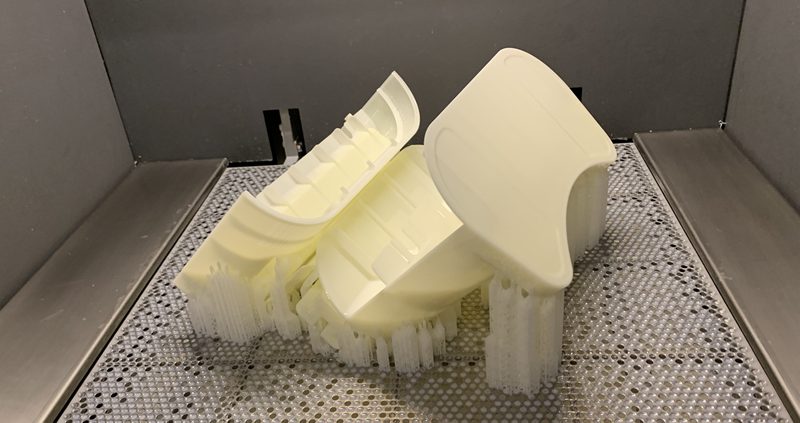

3D printing PLA material

3D printing PLA material

PLA (Poly Lactice Acid) is a new type of biodegradable material. It can be processed from starch raw materials , and the production process is pollution-free and can be degraded.

Material advantages:

Directly degradable environmentally friendly bioplastics, low melting point, small shrinkage ratio, not easy to warp or deform, good printing flatness, suitable for models that do not require processing.

Material weaknesses:

Temperatures above 60°C will deform PLA materials. PLA material is fragile and cannot be used to make handles for tools or parts that will drop repeatedly.

Precision:

0.2mm

Application:

Auto electronic lamps and other parts production.

Can be used for lens packaging fluid analysis RTV mold durable concept model wind test and other practical production activities

Note:

PLA can break if it is slightly bent and is not suitable for making thin things.