Why build prototypes in China?

This is a mini series on rapid prototyping in China.

You’ve got an investor meeting in two weeks. The electronics and software look solid and the mechanical and industrial design is ready. All that remains is re-creating this design in real life. You could work with the local machine shop. Or you could try making the prototype in China.

Why build a prototype in China? Cost and delivery time. Our clients in Silicon Valley have received prototypes from us faster than local shops (yes, even including shipping time!) and at significant cost savings (even including shipping cost!).

You might ask, where do the cost advantages come from? In short, labor and economies of scale.

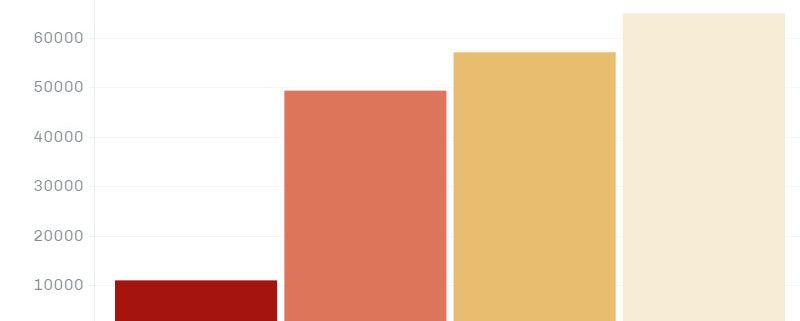

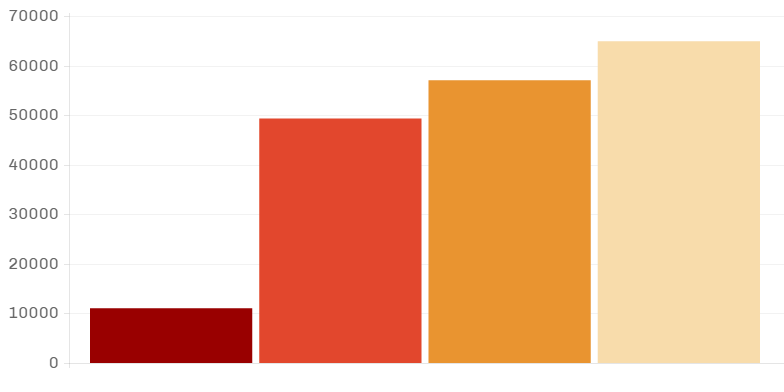

In the rapid prototyping business, after the initial fixed costs of purchasing equipment, one of the largest expenses is labor. I’m sure you know that wages are significantly lower in China than in the USA or Europe, but here’s some context. Take a CNC programmer for example:

CNC Programmer Pay (USD/year)

By CNC-ing prototypes in the USA, you are paying a wage premium of 4x – 6x!

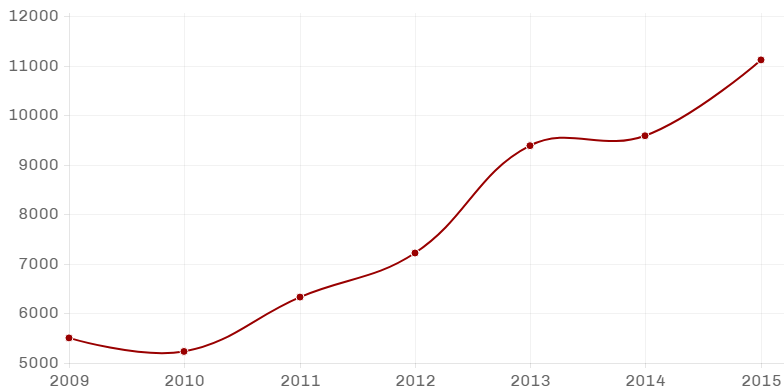

And don’t think for a moment that you are supporting tyrannical machine shop owners who are artificially depressing wages. Wages in Shenzhen, China have grown healthily in recent years. Again, take a CNC programmer for example:

CNC Programmer Wage Growth (USD/year)

CNC programmer wages have grown from about USD5.5k per year in 2009 to about USD11k per year in 2015, which comes out to about a 12% increase YoY. With a 12% wage increase YoY, wages will still be significantly lower than that of the USA in the foreseeable future. In addition, with China’s GDP growth slowing down, it will probably take a few decades for wages here to come close to other developed nations.

The other comparative advantage of economies of scale is a little more subtle. Some rapid prototyping shops have many different kinds of equipment to be able to make the right part and/or apply the desired finishing. However, having such a wide variety of equipment typically results in under-utilization.

Equipment under-utilization costs are, unfortunately, borne by the customer.

Here in the Shajing district of Shenzhen, China, each factory (or machine shop) is extremely specialized. A CNC shop would only do CNC; a power coating shop would only do powder coating. You might ask how does this work when your prototype requires many different processes? Well, this is the beauty of making prototypes here. Take a look at the manufacturing ecosystem around us:

Many, many, many factories all around us, all within a 30 minute drive.

Need the anodized aluminium finish like Apple’s Macbooks? There’s an anodizing factory about 1 km away. Need parts SLA 3D printed? Hop over to an SLA shop on the other side of town. Just take a look at the sheer number of factories around us in the map above (工厂 means factory in Chinese). And this doesn’t include the factories that are not listed on Baidu maps!

The ecosystem here allows prototypes with many processes to be made quickly and economically by extremely specialized personnel

Another benefit of this density of factories is competition and availability of resources. There are literally tens of thousands of CNC machines in Shenzhen and countless shops operating them, which means competition keeps job prices low for customers. More machines in a given area also means more parallel processing. If a project is extremely urgent and needs to be done as soon as physically possible, jobs can be sub-contracted to other shops to get your prototypes done in time for a big deadline.

The rich hardware ecosystem of Shenzhen also includes countless gurus of every industry (people who have been working in a particular field or job for 20-30 years). This is a hidden gem resource for many teams, particularly start-ups, as they can get invaluable feedback from these experts just by working in this environment and talking to the people, and ultimately get a few steps closer to launching the final product!

With such cost savings, why don’t you try making a prototype in China? To work with us, request a quote today!

References:

1. Self reported salaries in Shenzhen, China

2. Self reported salaries in USA