5-axis CNC machining production

5-axis CNC machining production

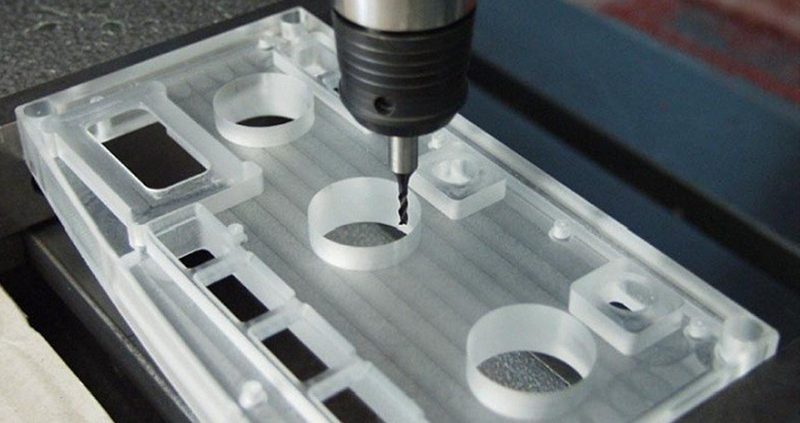

First we need to recognize what is the 5-axis CNC machining? 5-axis CNC machining is the use of computer numerical control (CNC) to relocate a device or part at the same time along 5 axes. The reducing tool moves constantly along each axis to ensure that the suggestion is constantly perpendicular to the part. This procedure permits you to equipment all sort of facility parts.

Benefits of 5-axis CNC machining

Solitary Configuration: 3-axis machines call for several configurations, which can bring about incorrect placement, higher expenses, as well as various other errors. With 5-axis CNC machining, you can maker complicated shapes in a solitary setup, increasing effectiveness, saving time, decreasing prices as well as stopping driver mistake.

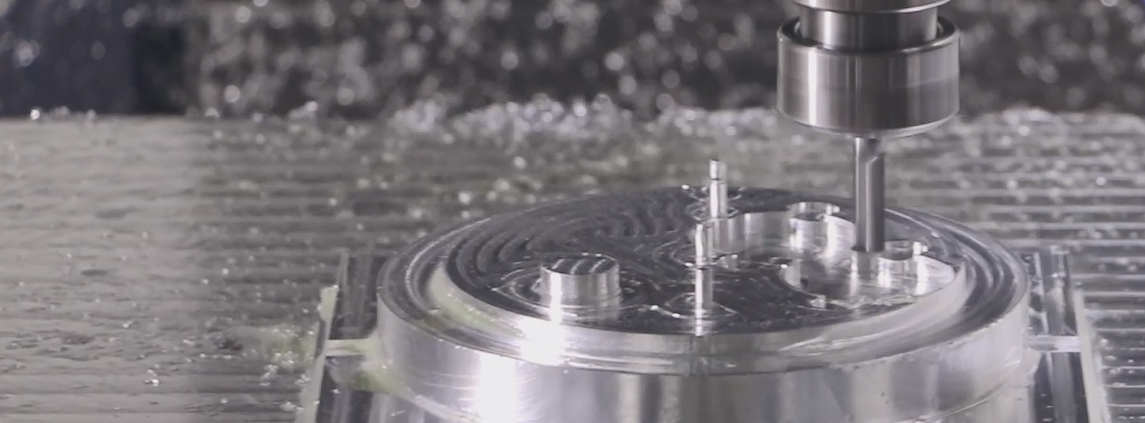

Shorter tools: 5-axis CNC machining allows you to utilize much shorter tools due to the fact that you can lower the head and position the device appropriately. This assists accomplish greater cutting speeds without placing excessive stress on the tool. Shorter cutting tools additionally lower device vibration, which can trigger tooth cavities as well as cores. You’ll see a far better surface coating because of much less vibration on the 5-axis device.

Complex Parts: 5-axis CNC machining process allows you to device complicated parts that would certainly or else need casting. If you have a low-volume production or model, you’ll have the ability to device the part in a couple of weeks, instead of waiting months for spreading.

Boosted device life: You can keep consistent chip load as well as ideal reducing setting to improve device cycle time as well as life.

Exploration: 5-axis CNC machining gives the capability to drill a collection of openings with different compound angles in time. This conserves a great deal of time– if you are making use of a 3-axis device, you will certainly require to make use of various settings for each face.

Accident evasion: the capability to turn the table or cutting device to stop accident with the tool owner

The E-make group has more than three decades of combined experience in prototype machining, CNC manufacturing.And has a top-level technological group of 25 peoples.If you need any aid, please feel free to contact us.