Where to learn cnc machining?

Where to learn cnc machining?

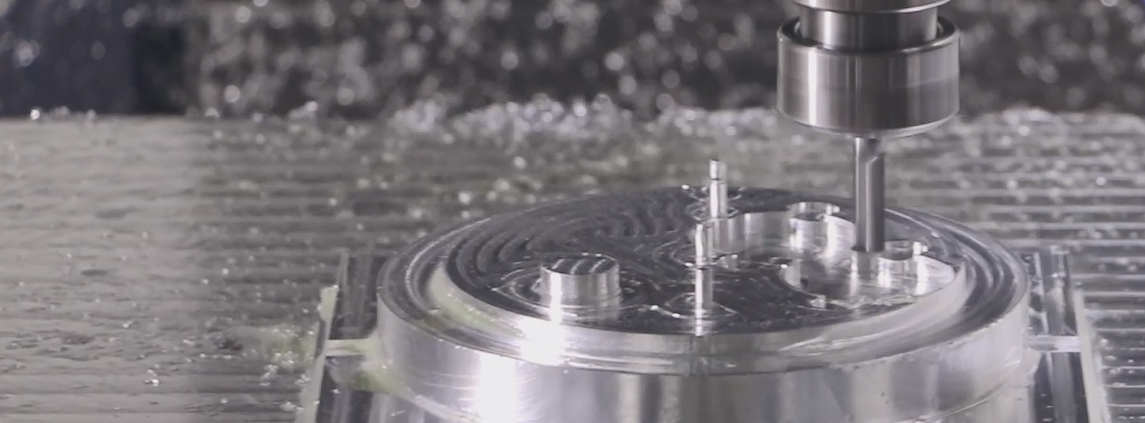

Everything before this topic is prep work. CNC Machining is where the rubber satisfies the road. All the actions of CNC before machining are just planning for the machining phase of the task. An easy meaning of machining is removing product. You eliminate product in numerous means to find up with the part or piece.

CNC Machining can be done on various kinds of product. For example, wood, steel, light weight aluminum, and rock. Machining normally has actually higher resistances associated with it. When machining, you are trying to do something a lot more accurate.

In machining, we make use of some sort of tool. This tool could be a mill, drill bit, end mill, router bit or various other tool. There are boundless variations of tools. CNC Tooling usually sets you back a fair amount of cash. Once you invest in your tooling though, you can use it repeatedly until it wears out. If you have a large variety of different tools, you will certainly be able to execute a huge variety of machining types.

Below is a checklist of common tooling utilized in CNC Machines:

Pierce bits

End mills

Plasma cutter

Dovetail cutter

Fly cutter

If you wish to consider different kinds of CNC tooling, most likely to one of these sources on the Internet:

Enco

Travers

McMasters-Carr

Grainger

Flip through a few of these providers’ magazines and you will certainly obtain a suggestion concerning the infinite designs of tooling.

CNC is made use of in the machining procedure. Normally, you can get better precision, quicker production, and general efficiencies when utilizing CNC machining. This is why it has ended up being so prominent. In the past, CNC machining was extremely pricey. With time, it has actually become somewhat affordable and currently people do it as a pastime. I am thinking that is why you are here.

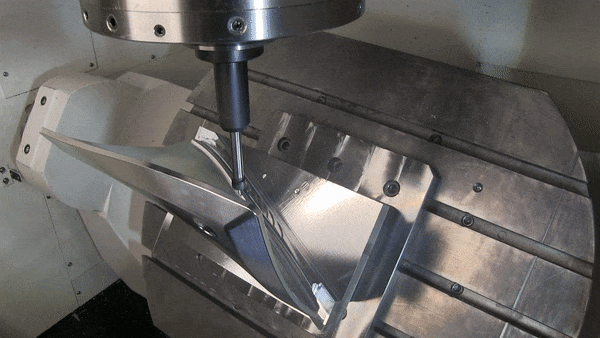

Right here are a couple of different kinds of CNC equipment that carry out various machining procedures:

Milling makers

Timber routers

Plasma cutters

Foam cutters

Press brakes

Turrets

Cutoff saws

The E-make team has greater than three decades of consolidated experience in model machining, CNC manufacturing.And has a top-level technical team of 25 peoples.The handling high quality of the quick production is steady, the handling accuracy is high, as well as the look is exquisite.If you require any type of aid, please do not hesitate to call us.