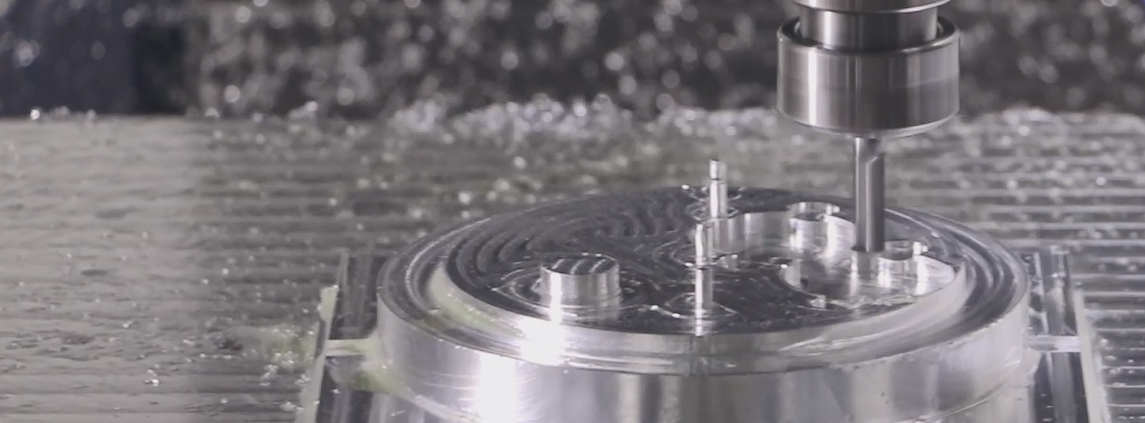

High Precision 5-axis CNC machining

High Precision 5-axis CNC machining

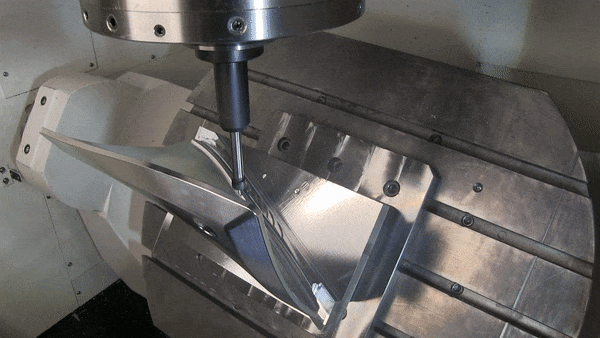

First we require to understand what is the 5-axis CNC machining? 5-axis CNC machining is the use of computer mathematical control (CNC) to move a tool or part concurrently along 5 axes. The cutting tool relocation constantly along each axis to make sure that the tip is always perpendicular to the component. This procedure allows you to equipment all type of facility parts.

Benefits of 5-axis CNC machining

Solitary Setup: 3-axis machines call for several setups, which can lead to incorrect placement, greater costs, and also various other errors. With 5-axis CNC machining, you can equipment complicated shapes in a single setup, increasing performance, saving time, lowering prices and avoiding operator mistake.

Shorter devices: 5-axis CNC machining permits you to use much shorter devices due to the fact that you can decrease the head and place the tool appropriately. This helps attain greater reducing rates without placing way too much pressure on the device. Much shorter cutting devices likewise lower tool vibration, which can create tooth cavities and cores. You’ll see a much better surface finish due to less vibration on the 5-axis machine.

Facility Components: 5-axis CNC machining procedure permits you to maker complicated components that would or else call for spreading. If you have a low-volume production or prototype, you’ll have the ability to device the part in a couple of weeks, as opposed to waiting months for spreading.

Increased tool life: You can keep constant chip tons and optimum cutting placement to boost tool cycle time and also life.

Drilling: 5-axis CNC machining offers the ability to drill a series of holes with various substance angles in time. This conserves a lot of time– if you are making use of a 3-axis device, you will require to utilize different settings for each face.

Crash evasion: the capability to tilt the table or cutting tool to avoid accident with the device owner.

The E-make group has greater than thirty years of combined experience in prototype machining, CNC machining.And has a high-level technical group of 25 peoples.The handling high quality of the quick manufacturing is steady, the handling accuracy is high, and also the appearance is exquisite.If you require any type of assistance, please do not hesitate to contact us.