1, mold industry market capacity analysis

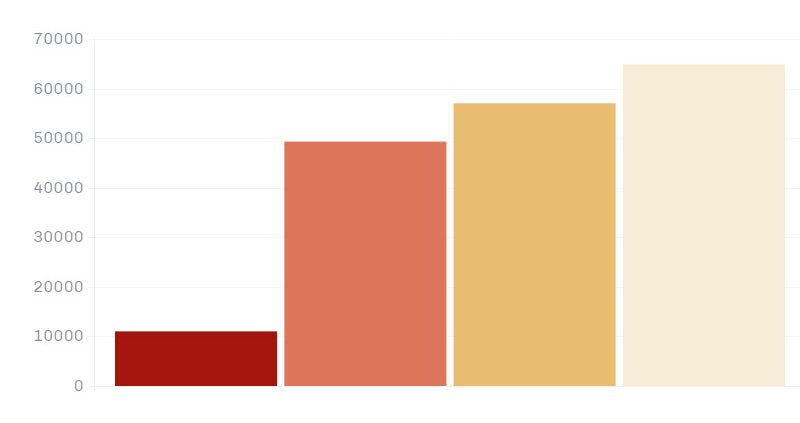

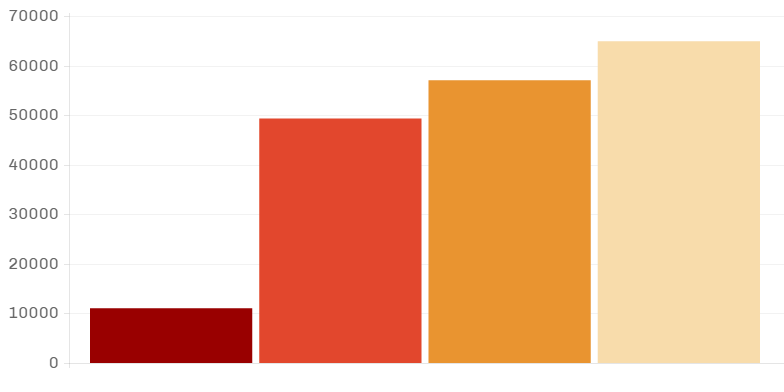

In recent years, China’s mold industry sales revenue continues to grow in 2014, the mold industry sales revenue of 2,474.19 billion yuan, an increase of 16.11%, by 2015, China’s mold industry sales revenue reached 249.848 billion yuan, an increase of 0.98%.

2009-2014, China’s mold industry sales rate in the fluctuations in the rise, 2013, 2014 China’s mold industry sales rate were 100.78% and 101.33%, indicating that China’s mold industry production and marketing convergence is better, more balanced supply and demand. China’s mold industry in 2015 sales rate of 98.33%, down from 2014.

China’s current mold industry trading market development is very rapid, showing a 15% -20% annual trend of growth rate. To 16% growth rate, to 2016, China’s mold industry sales revenue will reach 288.224 billion yuan. By 2021, China’s mold industry sales will be more than 600 billion yuan.

2, automotive mold industry market capacity analysis

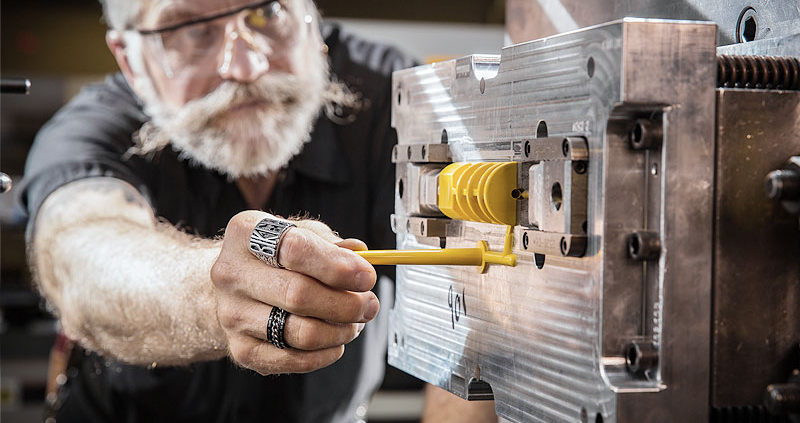

The development of automotive mold industry and the downstream industry is closely related to the development of the automotive industry, the downstream rapid and rapid development of the automotive industry will greatly promote the development of automotive mold industry. Mold is a consumable, the amount of large, more than 90% of the automotive industry parts from the mold, while the use of cold work, hot work, plastic mold steel, the average consumption of 0.12 tons per million car.

The future of the automotive industry towards lightweight body design and safety, electric vehicles and hydrogen-powered vehicles, new energy vehicles, as well as smart cars and other industrial development trends, will promote the development of automotive mold. By 2021, China’s auto production will reach nearly 35.55 million, the average annual growth rate of about 6.5%, while the demand for automotive mold will reach 386 tons.

3, the downstream industry market demand analysis

(1) the automotive industry

The development of automotive mold industry and the downstream industry is closely related to the development of the automotive industry, the downstream rapid and rapid development of the automotive industry will greatly promote the development of automotive mold industry. 90% of the parts in the automobile production need to rely on mold forming, the production of a general car generally need 1,000 to more than 1,500 sets of stamping die, about the vehicle production required for all die production value of about 40%. A country’s car production reflects the overall situation of the country’s car molds to a certain extent.

In 2015, the global automotive market in the SUV and Piccaz and other positive factors, the US auto market hit a record sales of 17.77 million new cars; China’s auto market showed a steady growth trend to 2,459.76 million new car sales, for seven consecutive years reelected the world’s first ; The European auto market has changed the previous downturn, a strong recovery, most countries have significant growth; according to the China Association of Automobile Manufacturers data, global car sales in 2015 reached 89.68 million. Global car sales in 2016 may be close to 90 million mark, the United States and Europe, car sales growth is more certain but not too much attention, and the other China’s new car sales stimulus package, it is possible to make global car sales to moderate growth rate, Estimated 2016 global car sales of 89.8 million.

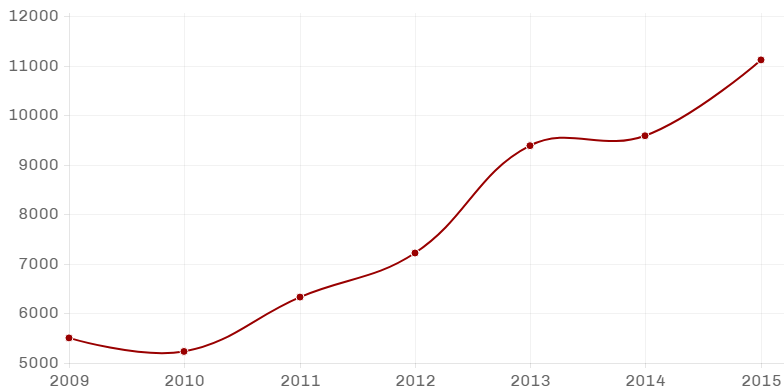

China’s auto production in 2009-2015 maintained a rapid growth momentum, from 1,379.10 million in 2009 increased to 24.5503 million in 2015, an average annual increase of 15.64%. 2016 In the first half of the year, China’s automobile production was 1,289.22 million, up 6.59% from a year earlier.

China in 2009 to push the car to the countryside policy, proposed a total of 4 trillion yuan subsidy measures, making China’s car sales in one fell swoop than the United States, becoming the world’s largest car market. In 2009, China’s auto sales showed a rapid growth trend. In 2009, the sales growth rate of automobile was the highest in recent years, reaching 45.42%. By 2011, car sales were 2,198.41 million, up 13.87% year on year and sales in 2014 increased to 2,349,900 Vehicles, an increase of 6.86%. Car sales in 2015 was 2,459.76 million, an increase of 4.71%. China’s car sales in the first half of 2016 was 1,282.98 million, an increase of 8.27 percentage points over the same period last year. China’s auto sales growth has slowed, but still maintain the momentum of successive years of growth. China Automobile Industry Association estimated that China’s auto sales in 2016 26.28 million units, an increase of 6.8%. 2025 car sales will reach 30 million.

China as the world’s largest auto market, but thousands of people average car ownership is much lower than the level of developed countries in Europe and America, China’s thousands of car ownership of about 120, compared to Western Europe and North America about 500, or a big gap, with With the increase in income and living standards, consumer demand upgrades, new car market demand is still large, so China’s future growth expectations and space is still great.

(2) home appliance industry

Household appliances industry needs a variety of stamping dies and injection molds, mold is another big user industry, the current home appliance manufacturing mold market share of more than 80%, fully self-sufficient, and domestic mold manufacturing enterprises in large LCD TV plastic mold, Backplane stamping die and other molding technology requires a higher mold production is also fully capable, with the appliance market competition is heating up, shell design has become an important part of the home appliance shell color, feel, precision, wall thickness and so on New requirements, the demand for new molds, the downstream home appliance industry, the rapid and rapid development will greatly promote the development of home appliance mold industry.

2015 China’s total sales of LCD TV 12,224 million units, an increase of 1.6%. Domestic sales, China’s LCD TV in 2015, total shipments of 5,120,30 million units, an increase of 2.6%. According to the enterprise, the six major brands for the Skyworth, Hisense, TCL, Konka, Changhong, Haier; Skyworth, Hisense shipments have more than 900 million units. Export, the main market, according to the country do not look, the continents are showing positive growth in 2015, China’s total exports of LCD TV 7,103,200 units, up by 0.9% year on year.