Material For Aluminum Prototype

1.Pure aluminum plate;

In all of the aluminum plate series,pure aluminum plate is the one that including most aluminum,the purity can over 99%,which is widely be use for conventional industrial.Therefore,the production process of pure aluminum plate is more simple and the price is more cheap.The material code we usually use of the pure aluminum plate is 1050,1060 and 1100.

2.Aluminum alloy plate;

Aluminum alloy plate series 2 with better hardness,include cuprum about 3-5%,which is a parts of aviation material.

Aluminum alloy plate series 3,including manganese about 1-1.5%,is commonly used in making car prototype,refrigerator prototype because it has good rust protection.Except that,Aluminum3003,3004 and 3A21 is usually use for making medical prototype,home appliance and so on.

Aluminum alloy plate series 4 including silicon about 4.5-6%,is a nice corrosion resistance material that usually be used for making mechanical parts,building parts,welding parts,etc.

Aluminum alloy plate series 5,we also call it aluminium magnesium alloy because it includes magnesium element about 3-5%.The feature of aluminum alloy plate series 5 is low density,high tensile strength and elongation,so that it will be use for aviation,such as fuel tanker.Also,it is a good material for wire drawing process.

Aluminum alloy plate series 6 including magnesium,silicon and other element,has both of aluminum4 and aluminum5 ‘s advantages,also easy for coating.What we usually use is aluminum 6061 and aluminum 6063 for prototyping.

Aluminum alloy plate series 7 with high hardness,high strength and nice wear-resistant,specially the aluminum 7075, is commonly used for making aluminum alloy plane model.

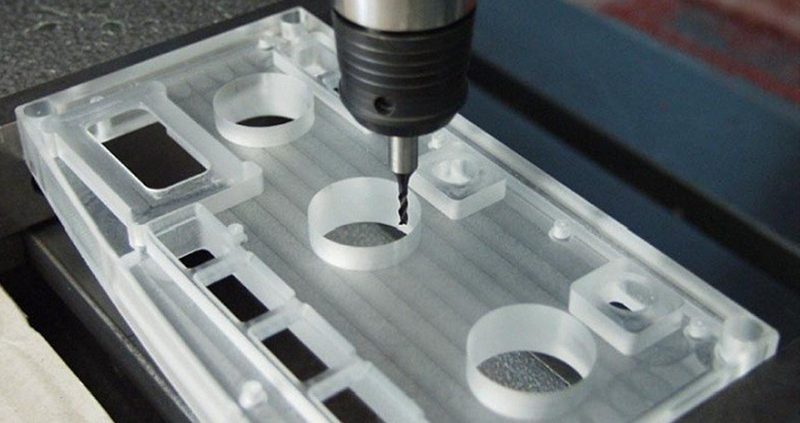

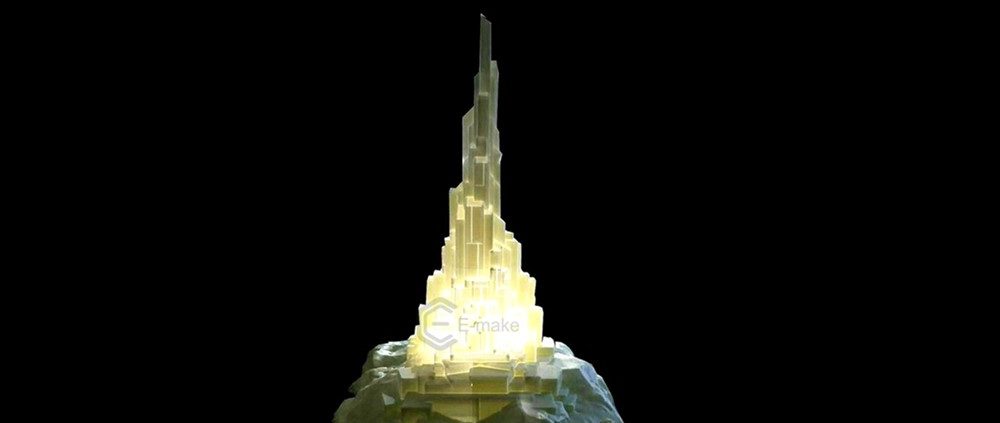

What kind of aluminum is best for machining your prototype,is up to your requirement of the product.Shenzhen E-Make Model Technology Co., Ltd is professional in CNC manufacturing,is welcome to contact us if you want to customized your prototype!