How 5-axis CNC Machining Work?

How 5-axis CNC Machining Work?

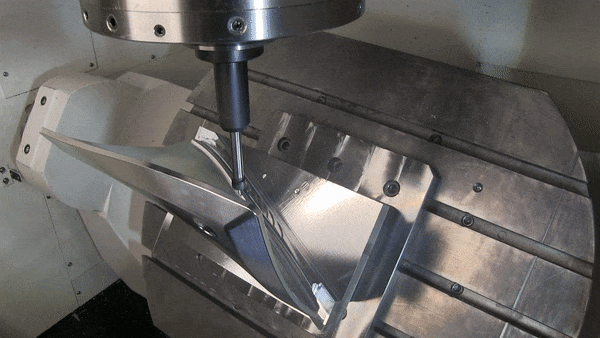

First we need to recognize what is the 5-axis CNC machining? 5-axis CNC machining is using computer mathematical control (CNC) to move a tool or component simultaneously along 5 axes. The reducing device relocation constantly along each axis to ensure that the suggestion is always perpendicular to the component. This process allows you to device all type of complicated components.

Benefits of 5-axis CNC machining

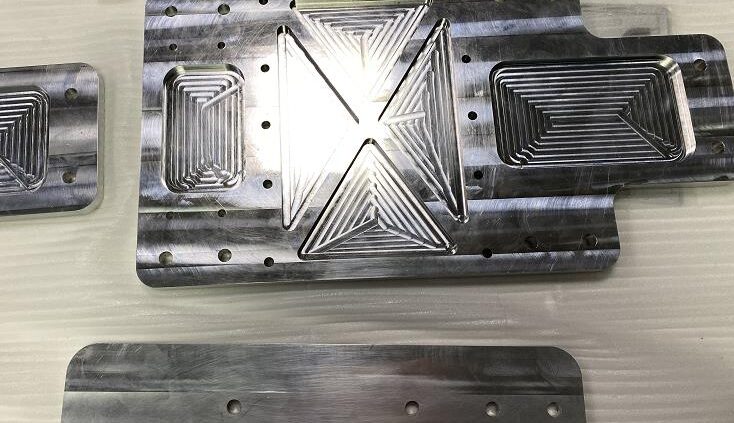

Single Setup: 3-axis machines require numerous arrangements, which can lead to incorrect positioning, greater expenses, as well as other mistakes. With 5-axis CNC machining, you can maker facility forms in a solitary arrangement, enhancing effectiveness, conserving time, lowering expenses and also preventing driver error.

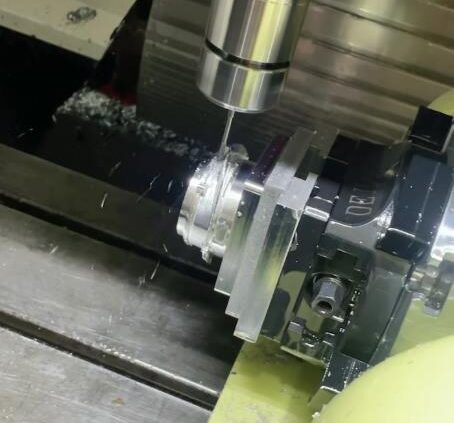

Much shorter devices: 5-axis CNC machining enables you to utilize much shorter tools because you can lower the head and also position the tool appropriately. This helps achieve higher cutting rates without placing way too much stress on the device. Shorter cutting devices also minimize tool resonance, which can cause cavities as well as cores. You’ll see a far better surface coating due to much less vibration on the 5-axis machine.

Complex Components: 5-axis CNC machining process permits you to maker complex components that would certainly otherwise require spreading. If you have a low-volume manufacturing or model, you’ll be able to device the part in a few weeks, instead of waiting months for spreading.

Raised tool life: You can keep constant chip lots as well as optimal cutting position to boost device cycle time as well as life.

Boring: 5-axis CNC machining provides the capability to drill a series of openings with various compound angles in time. This conserves a lot of time– if you are making use of a 3-axis machine, you will need to make use of various setups for every face.

Crash avoidance: the capacity to tilt the table or reducing tool to avoid collision with the tool holder

The E-make group has more than three decades of combined experience in model machining, CNC manufacturing. If you require any help, please do not hesitate to contact us.