CNC process

CNC process

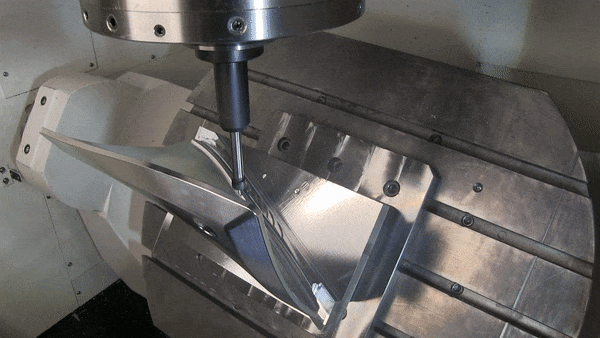

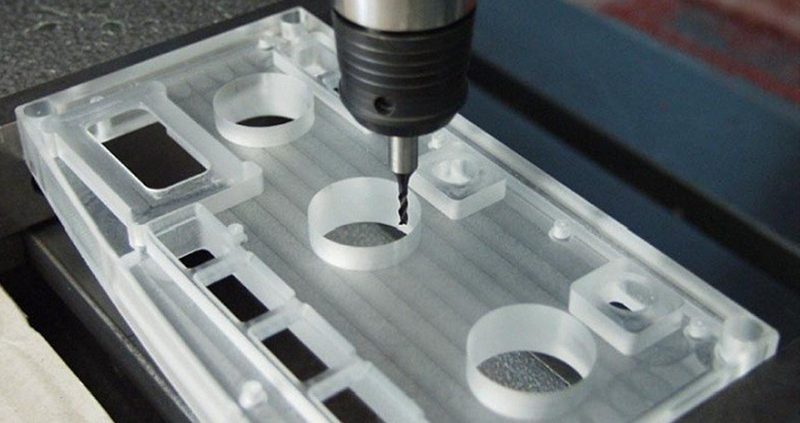

Everything before this topic is prep work. CNC Machining is where the rubber meets the roadway. All the steps of CNC prior to machining are simply getting ready for the machining stage of the task. A basic interpretation of machining is removing material. You get rid of product in numerous means to find up with the component or piece.

CNC Machining can be done on numerous kinds of material. For example, timber, steel, light weight aluminum, as well as stone. Machining generally has actually greater resistances connected with it. When machining, you are trying to do something much more accurate.

In machining, we use some kind of tool. This tool could be a mill, drill bit, end mill, router bit or other tool. There are unlimited variations of tools. CNC Tooling generally costs a fair quantity of cash. When you buy your tooling though, you can use it over and over until it wears out. If you have a large variety of different tools, you will be able to perform a big variety of machining kinds.

Below is a checklist of typical tooling used in CNC Machines:

Drill little bits

End mills

Plasma cutter

Dovetail cutter

Fly cutter

If you wish to consider different types of CNC tooling, most likely to among these resources on the web:

Enco

Travers

McMasters-Carr

Grainger

Flip through a few of these vendors’ catalogs as well as you will obtain a concept concerning the limitless styles of tooling.

CNC is used in the machining process. Usually, you can improve precision, quicker production, as well as general effectiveness when utilizing CNC machining. This is why it has actually become so preferred. In the past, CNC machining was extremely pricey. With time, it has become rather inexpensive as well as currently people do it as a hobby. I am guessing that is why you are here.

Right here are a couple of various kinds of CNC equipment that carry out numerous machining processes:

Milling equipment

Wood routers

Plasma cutters

Foam cutters

Press brakes

Lathes

Cutoff saws

The E-make team has greater than thirty years of combined experience in model machining, CNC manufacturing.If you need any aid, please feel free to contact us.