Application of ABS material in 3D printing

ABS is one of the main materials for 3D printing.The reason why it can become a consumable for 3D printing is determined by its characteristics. ABS materials have heat resistance,impact resistance,low temperature resistance,chemical resistance and excellent electrical properties,Product dimension stability and other characteristics.

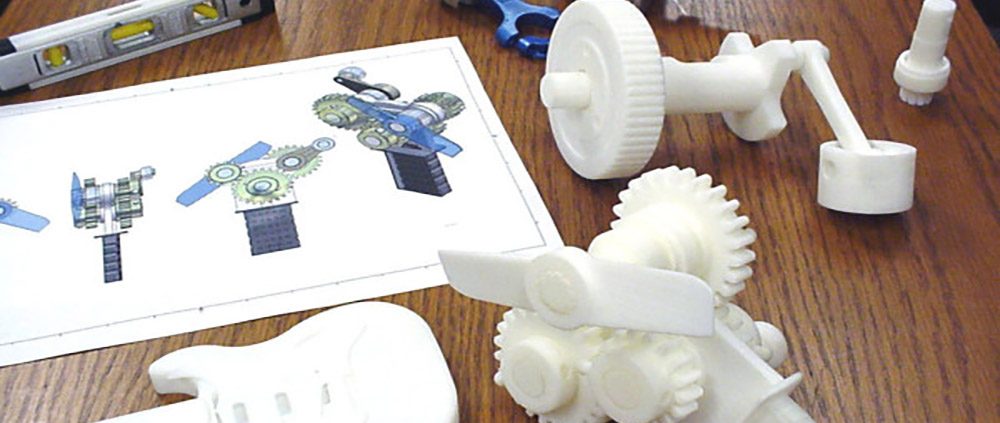

At present,ABS is the most stable material among 3D printing materials. It has good hot melt and impact strength,and it is also the preferred engineering plastic for fused deposition molding 3D printing process.For now,ABS is mainly pre-made into silk and powdered.The application range of ABS materials covers almost all daily necessities,engineering supplies and some mechanical supplies,and has a wide range of applications in automobiles,home appliances,consumer electronics and other fields.

Printing performance:

- ABS materialis quite easy to print.No matter what kind of extruder is used,the material will be extruded smoothly without worrying about clogging or solidification.However,the steps of ABS material after the extruder are a bit difficult.ABS material has the characteristic of shrinking when exposed to cold,and will partially fall off the heating plate and hang in the air,then it will be causing problems.In addition,if the height of the products that needs 3D printing is very high,the ABS material sometimes peels off the entire layer during the 3d printing process.Therefore,the heating plate cannot be omitted when ABS material is used for 3d printing.

- ABS material is relatively flexible,so it is suitable for making wearable products.

Strength:As long as 3D printing is carried out at an appropriate temperature and the layers of materials are firmly adhered,the strength of ABS will become quite high.But the ABS material is also flexible after 3D printing,even if it is under pressure,it will only bend and not break.

Odor: The biggest disadvantage of ABS material is that it produces a strong odor during 3d printing.Regardless of the material,it is recommended that you perform 3D printing in a well-ventilated room. This is especially true when using ABS materials.

ABS-M30 is a production-grade plastic that is specially designed for 3D printing with FDM technology.This strong and common material helps to test and repeat the work more frequently,Ultimately reduce risks and create better products,speeding up the time to market.

Due to performance reasons and the price is more suitable,3d printing ABS material it is very suitable for conceptual models and parts with medium requirements, including functional prototypes.The colors of ABS material are natural color,white,black,dark gray,red and blue.In addition,the color can be customized when 3d printing.

The E-make company is a rapid prototyping manufacturer.

Our factory provides high quantity 3D printing、Vacuum casting service、CNC machining service and injection molding service.

All information from customers was kept secret,we can sign NDA with customer before starting any work.

If you need any help,please feel free to contact us!