How is the quality and safety of plastic molds guaranteed?

Plastic mold processing refers to the plastic molding and plastic blank tool processing, with the upper mold and the next two parts, its basic features are as follows:

(1) high precision machining requirements

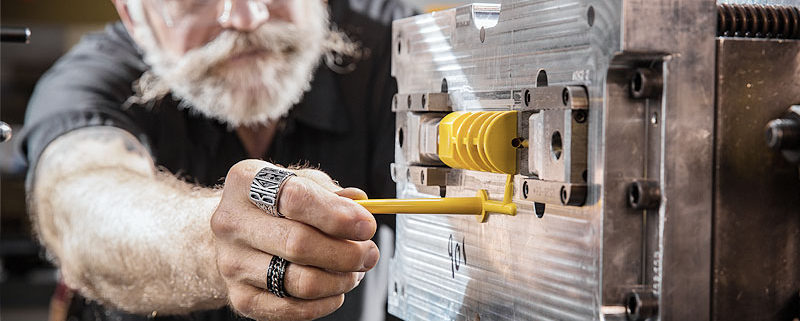

A mold is generally composed of die, punch and mold frame, and some may also be more than a split module. So the combination of the upper and lower molds, the combination of the insert and the cavity, the punching between the modules requires a high degree of machining accuracy. Precision precision of the mold is often up to a micron level.

(2) complex surface

Some products such as car covers, aircraft parts, toys, household appliances, the shape of the surface is a combination of a variety of surfaces, so the mold cavity surface is very complex. Some surfaces must be processed mathematically.

(3) small batch

The production of molds is not mass production in batches, and in many cases it often produces only one pay.

(4) process more

Mold processing always used milling, boring, drilling, hinge and tapping and other processes.

(5) repeat production

The use of mold is life-long. When the use of a pair of mold over its life, it is necessary to replace the new mold, so the mold production is often repeatable.

(6) profiling

Mold production sometimes no pattern, no data, but also according to the physical copy processing. This requires high imitation precision, no deformation.

(7) mold material is excellent, high hardness

The main material of the mold is made of high quality alloy steel, especially the high life mold, often used Crl2, CrWMn and other lignocellitic steel. This kind of steel from rough forging, processing to heat treatment are strict requirements. So the preparation of processing technology can not be ignored, heat treatment deformation is also the need to seriously deal with the problem.

Understand the basic characteristics of plastic mold processing, in the selection of machine tools to meet the processing requirements as much as possible. Such as the function of the CNC system to be strong, high precision machine, rigid, thermal stability is better, with copy function. Official website: http: //www.szckr88.com/

Shenzhen Chuangkai Rui Technology Co., Ltd. is a company engaged in product design, mold making, plastic products production, set of plastic electronic products manufacturing technology companies. Since its establishment in 2004, has experienced seven years of wind and rain. From the original single plastic mold manufacturing workshop, the development of today set design, research and development, manufacturing and services as one of the modern technology enterprises. Today, the company has a wealth of service and innovative sense of high-quality professional team, the production of gifts, daily necessities, electronic plastic parts and other products exported to Europe and the United States, Asia-Pacific, Hong Kong, Taiwan and other countries and regions. And today all this is derived from the original flash of the idea – the aesthetic must adhere to.

Kay people insist that design not only gives people a sense of beauty, but also give a new definition of value. Products due to emotional design and the United States, because of emotional design and human nature, because of emotional design and have a new value. Modern industrial products in addition to high efficiency, high quality, but should meet the higher aesthetic requirements of modern people. Kay people adhere to the personality of the artistic creativity and common science and technology, adhere to the aesthetic design and high-quality manufacturing concept, in order to give the product content and soul.

Chuang Kai Rui look forward to working with your win-win cooperation. Main products are: plastic shell, plastic mold, plastic daily necessities, etc., want to know more about plastic products, please call to the plastic mold company or large injection molding machine processing plant.