What is the process of cnc machining

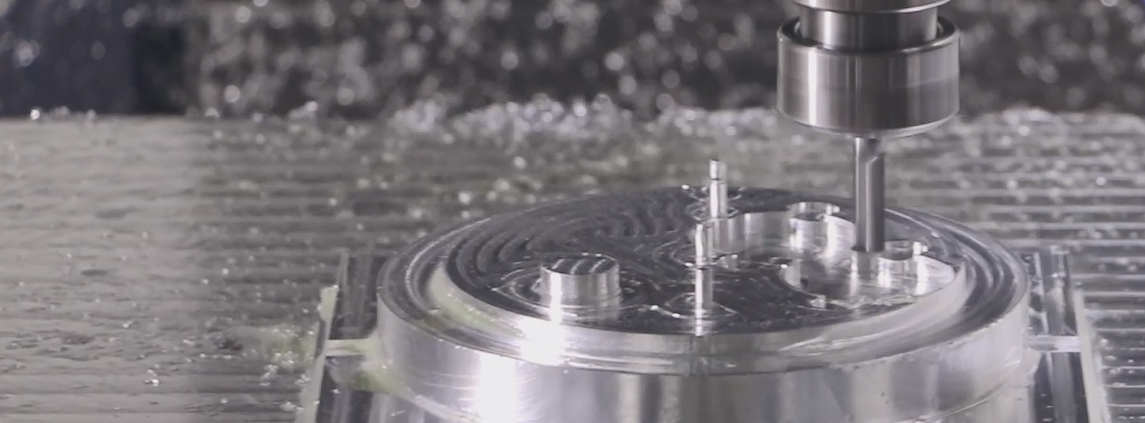

CNC Machining

Every little thing before this subject is prep work. CNC Machining is where the rubber satisfies the road. All the steps of CNC prior to machining are simply getting ready for the machining stage of the job. A simple definition of machining is removing product. You eliminate product in various ways ahead up with the component or item.

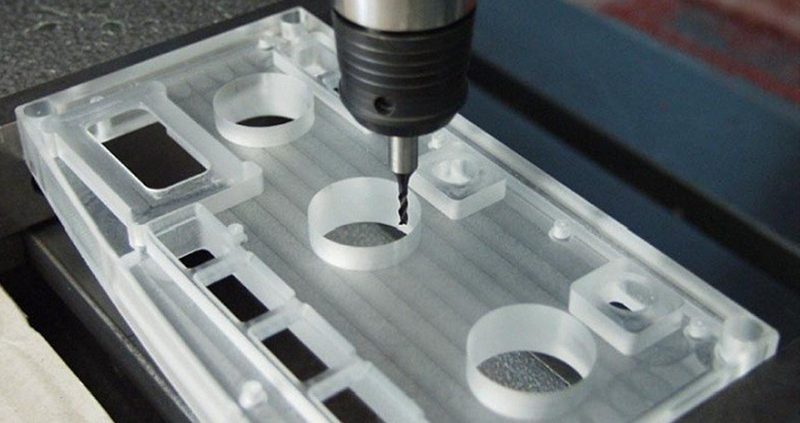

CNC Machining can be executed on many kinds of product. For example, timber, steel, light weight aluminum, and stone. Machining normally has higher tolerances connected with it. When machining, you are attempting to do something more accurate.

In machining, we utilize some type of tool. This tool could be a mill, drill little bit, end mill, router little bit or various other device. There are boundless variations of devices. CNC Tooling usually sets you back a fair quantity of cash. Once you purchase your tooling though, you can use it repeatedly till it breaks. If you have a big selection of different tools, you will be able to perform a huge variety of machining types.

Here is a list of usual tooling utilized in CNC Machines:

Drill little bits

End mills

Plasma cutter

Dovetail cutter

Fly cutter

If you would love to look at various kinds of CNC tooling, most likely to one of these sources online:

Enco

Travers

McMasters-Carr

Grainger

Scan a few of these distributors’ brochures and you will get a suggestion concerning the limitless designs of tooling.

CNC is made use of in the machining procedure. Typically, you can improve accuracy, quicker production, as well as general performances when using CNC machining. This is why it has actually come to be so preferred. In the past, CNC machining was extremely expensive. Over time, it has actually become rather low-cost and also now people do it as a hobby. I am thinking that is why you are right here.

Here are a few various sorts of CNC makers that execute numerous machining processes:

Milling makers

Wood routers

Plasma cutters

Foam cutters

Press brakes

Lathes

Cutoff saws

People have efficiently applied CNC to virtually any type of type of activity control. The only thing that will limit you is your creative imagination.