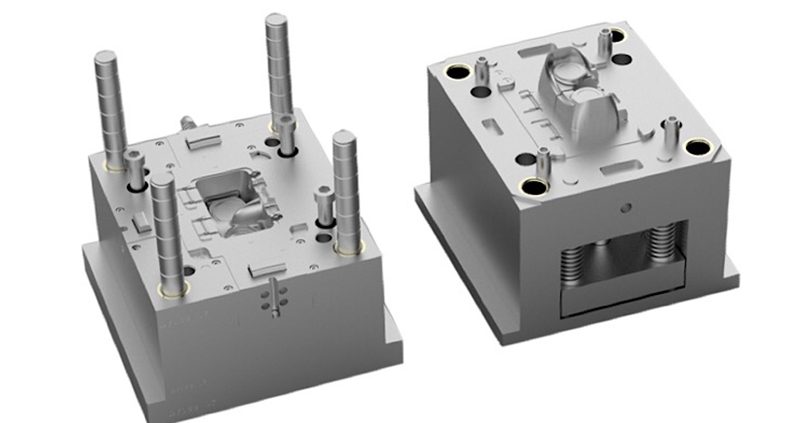

The Difference Between Steel Mold And Aluminum Mold

The Difference Between Steel Mold And Aluminum Mold

The mold we usually use for injection molding process is steel mold or aluminum mold.Below is some difference between them.

1.Tool life.

The steel mold is with high hardness,so it is more wearable and long life.The aluminum mold is opposite,which is with low hardness and are easy to out of shape .So we will use steel mold for mass production with large quantity and use aluminum mold for small batch production.

2.Tool weight.

The steel mold is more heavier.

3.Tool cost.

For producing same product,the structure of steel mold is more complicated and are more hard to be made,so the steel mold takes more machining cost and machining time.On the contrary,aluminum mold is more easy to machining and takes less machining cost.

4.The mirror polishing property of tool.

The mirror polishing property of steel mold is better than aluminum mold.