5-axis CNC machining Service

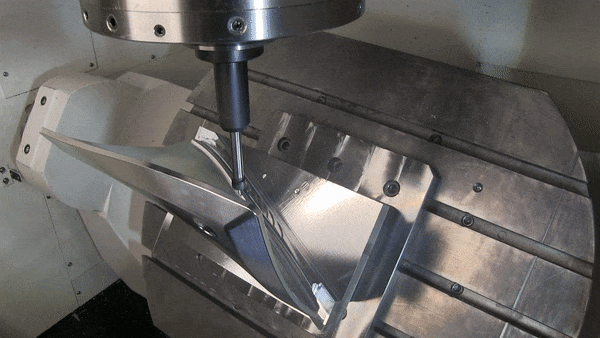

First we need to know what is the 5-axis CNC machining? 5-axis CNC machining is the use of computer numerical control (CNC) to move a tool or part simultaneously along five axes. The cutting tool moves continuously along each axis so that the tip is always perpendicular to the part. This process allows you to machine all kinds of complex parts.

Advantages of 5-axis CNC machining

Single Setup: 3-axis machines require multiple setups, which can lead to incorrect alignment, higher costs, and other errors. With 5-axis CNC machining, you can machine complex shapes in a single setup, increasing efficiency, saving time, reducing costs and preventing operator error.

Shorter tools: 5-axis CNC machining allows you to use shorter tools because you can lower the head and position the tool properly. This helps achieve higher cutting speeds without putting too much pressure on the tool. Shorter cutting tools also reduce tool vibration, which can cause cavities and cores. You’ll see a better surface finish due to less vibration on the 5-axis machine.

Complex Parts: 5-axis CNC machining process allows you to machine complex parts that would otherwise require casting. If you have a low-volume production or prototype, you’ll be able to machine the part in a few weeks, rather than waiting months for casting.

Increased tool life: You can maintain constant chip load and optimal cutting position to improve tool cycle time and life.

Drilling: 5-axis CNC machining provides the ability to drill a series of holes with various compound angles in time. This saves a lot of time – if you are using a 3-axis machine, you will need to use different settings for each face.

Collision avoidance: the ability to tilt the table or cutting tool to prevent collision with the tool holder

Here’s the advantages of 5-axis CNC machining.