CNC machining and rapid prototype

CNC machining and rapid prototype

In the layout procedure of R&D items, after they have completed the design drawings, one of the important things they intend to do most is to know what the products they create resemble in reality, and whether the appearance of the products is consistent with their own layout ideas., Is the framework design of the item sensible, etc? Prototype manufacturing is created in feedback to this need.

Classification of prototypes:

Prototypes can be divided into guidebook and mathematical control models according to the manufacturing methods:

Hands-on prototype: The major workload is done by hand.

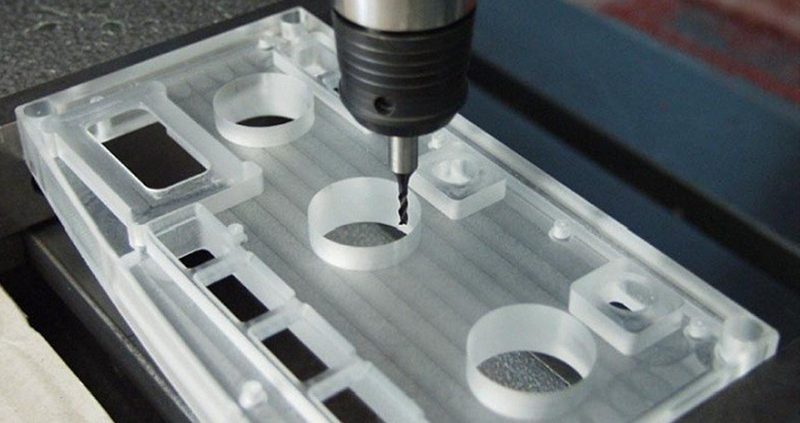

CNC prototype: The primary workload is finished by CNC machine devices, and relying on the equipment made use of, it can be split into laser rapid prototyping (RP, Rapid Prototyping) prototypes as well as machining facility (CNC) prototypes

A: RP model: generally produced by laser fast prototyping technology.

B: CNC prototype: mainly produced by machining facility.

RP prototypes have their very own advantages compared to CNC prototypes: the advantages of RP prototypes are primarily in its rapidity, however it is primarily developed by piling innovation, so RP prototypes are usually fairly harsh, and there are particular demands for the wall surface density of the product, as an example, If the wall thickness is also thin, it can not be produced.

The advantage of CNC model is that it can properly mirror the information expressed in the drawings, and the surface high quality of CNC model is high, particularly after the surface spraying and also silk printing are completed, it is even more attractive than the product generated after the mold is opened. Therefore, CNC prototype production has increasingly come to be the mainstream of prototype production.

According to the materials utilized in production, prototypes can be divided into plastic and also steel models:

( 1) Plastic models: The raw products are plastic, mainly for models of plastic items, such as tvs, displays, telephones, and so forth.

( 2) Steel prototypes: The raw materials are aluminum-magnesium alloys and other steel materials, mainly for premium products, such as notebook computers, premium single gamers, MP3 players, CD players, and so on.

The requirement of prototype production

( 1 )Design examination

The prototype is not just noticeable, yet also touchable. It can directly show the designer’s imagination in the form of physical items, avoiding the drawback of “attracting to look good yet not to make it look great”. Consequently, prototype production is important in the process of brand-new product growth as well as item shape examination.

( 2 )Examine the architectural design

Since the model is assembleable, it can with ease mirror the reasonableness of the framework as well as the simplicity of installation. It is convenient to find and also address issues early.

( 3 )Aviod the danger of directly make molds

Because the cost of mold manufacturing is generally really high, reasonably big mold and mildews are worth thousands of thousands or perhaps millions. If unreasonable framework or other troubles are discovered in the process of opening up the mold, the loss can be envisioned. prototype production can prevent this loss and also decrease the threat of mold opening.

The surface area of model:1, electroplate.2, anodized.3, paint.4, polish.5, lase.etc.

If you have a brand-new item that need to make a model to make examination and check the architectural design.Please do not hesitate to contact us.As a prototype manufacturing facility for 20 years.We can make any kind of item.