What is sheet metal prototype processing?

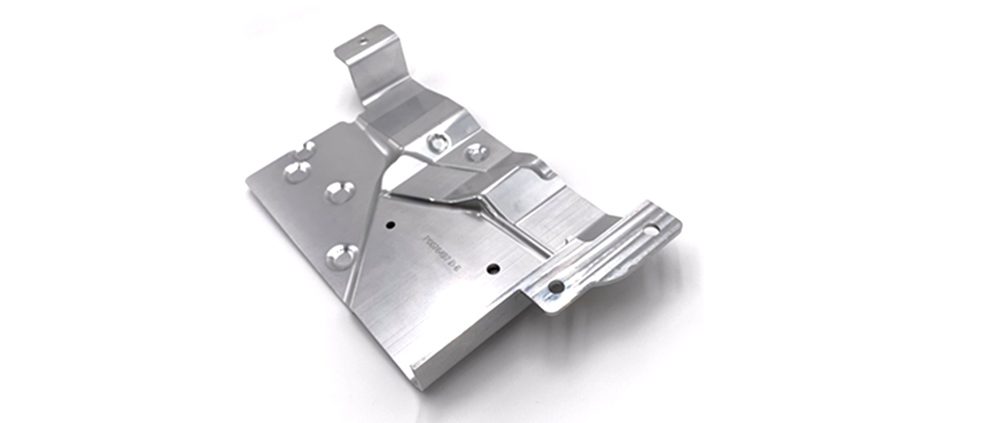

Sheet metal processing refers to the processing technology of sheet metal, and sheet metal parts are thin metal parts.The sheet metal process is an induction cold-working hand plate manufacturing process for metal sheets (usually below 6mm), including shearing, punching/cutting/compounding, folding, welding, riveting, splicing, forming (such as car body), etc.It is plastically deformed by craftsmanship or die stamping to form the desired shape and size, and can be further welded or a small amount of mechanical processing to form more complex parts, such as chimneys, iron stoves, and car shells commonly used in life.The obvious feature is the same thickness of the same part.The three most important processes of sheet metal processing are shearing, punching/cutting, and folding.

The E-make team has more than 30 years of combined experience in prototype machining, CNC manufacturing, vacuum casting service and sheet metal service.And has a high-level technological group of 25 peoples.The processing quality of the rapid manufacturing is stable, the processing precision is high, and the appearance is exquisite. E-make company has been providing high quality rapid prototype manufacturing services for major enterprises.

If you need any help,please feel free to contact us!