CNC Machining parts service

CNC Machining parts service

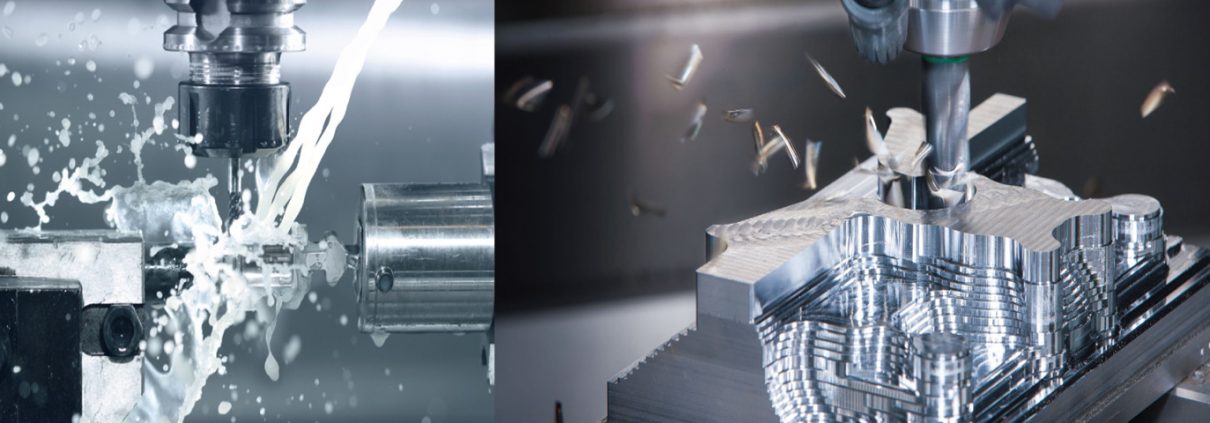

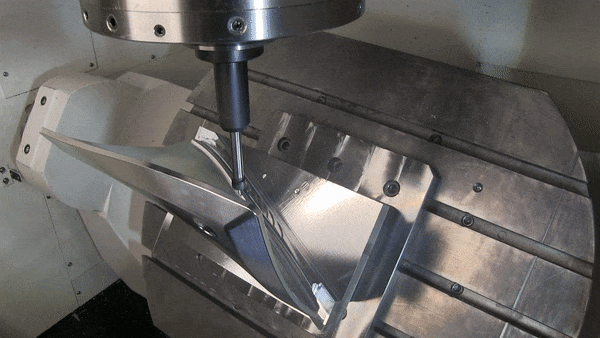

Every little thing before this subject is preparation. CNC Machining is where the rubber meets the road. All the steps of CNC prior to machining are just getting ready for the machining stage of the task. A straightforward interpretation of machining is eliminating product. You eliminate material in different ways to come up with the component or piece.

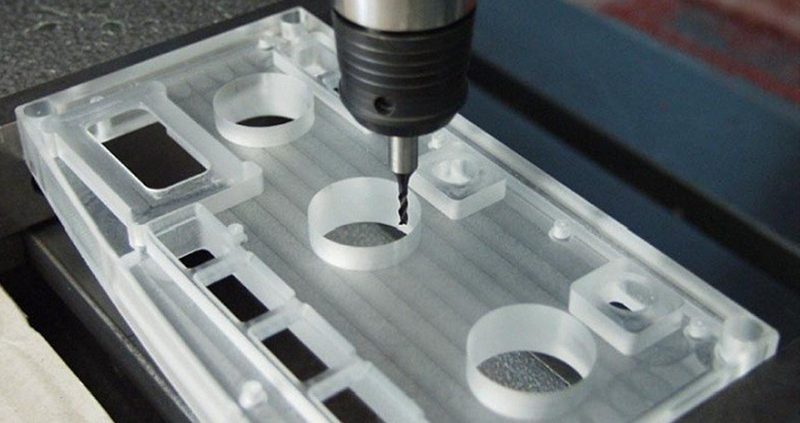

CNC Machining can be carried out on various kinds of material. For instance, timber, steel, aluminum, as well as stone. Machining normally has actually greater tolerances associated with it. When machining, you are trying to do something extra exact.

In machining, we make use of some sort of device. This tool could be a mill, drill little bit, end mill, router little bit or other device. There are boundless variants of tools. CNC Tooling normally sets you back a reasonable quantity of money. Once you invest in your tooling though, you can use it over and over till it wears out. If you have a big selection of various tools, you will have the ability to execute a huge variety of machining kinds.

Right here is a listing of common tooling utilized in CNC Machines:

1.Pierce little bits

2.End mills

3.Plasma cutter

4.Dovetail cutter

5.Fly cutter

If you would love to take a look at different sorts of CNC tooling, go to among these sources on the net:

Enco

Travers

McMasters-Carr

Grainger

Browse a few of these providers’ directories and also you will obtain a concept about the infinite designs of tooling.

You can also find out more on our website!

CNC is made use of in the machining procedure. Usually, you can get better precision, quicker manufacturing, and general efficiencies when utilizing CNC machining. This is why it has become so popular. In the past, CNC machining was very expensive. In time, it has become somewhat affordable as well as now individuals do it as a leisure activity. I am guessing that is why you are below.

Below are a couple of different kinds of CNC machines that carry out different machining procedures:

Milling makers

Timber routers

Plasma cutters

Foam cutters

Press brakes

Turrets

Cutoff saws

People have effectively applied CNC to practically any type of type of activity control. The only thing that will certainly restrict you is your creativity.

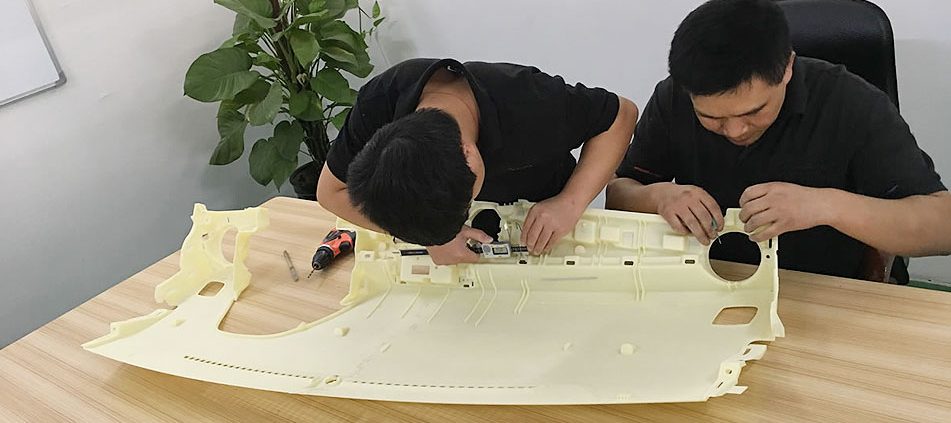

The E-make group has greater than thirty years of mixed experience in prototype machining, CNC machining aluminum parts.And has a top-level technical team of 25 peoples.The processing high quality of the fast manufacturing is steady, the handling accuracy is high, as well as the appearance is exquisite.If you need any type of assistance, please feel free to contact us.