The Importance Of Painting Prototype

The Importance Of Painting Prototype

Painting process is one of the surface treatment that be widely use for products.Below is some advantage of the painting for product.

1.Painting can cover the slight flaw on the surface of product;

2.Product can obtain a variety of surfaces by painting,such as color and gloss.

3.Increasing the surface hardness and the conflict of resistance of parts.

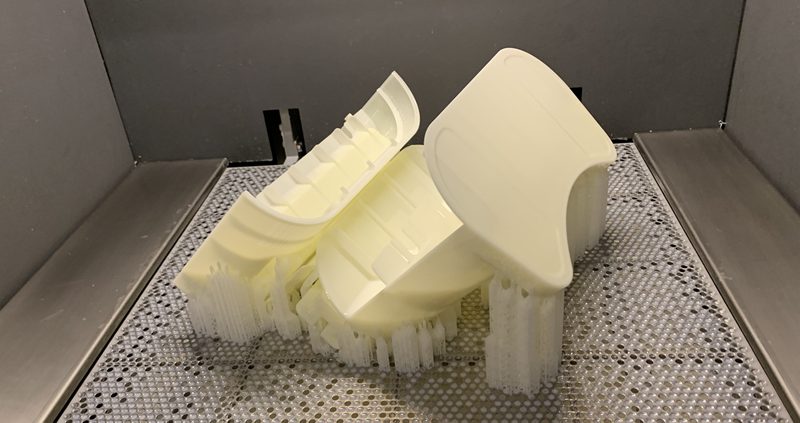

In a word,painting can beautify the appearance of product and protect the product structure from damage.For example,the appearance of the CNC machined prototype after painting is very closed with the finished product.But there are some plastic is without stronger color adhesion and is hard to painting color,such as POM and PP.

E-make is professional in making rapid prototype,it is welcome to contact us to make your product.