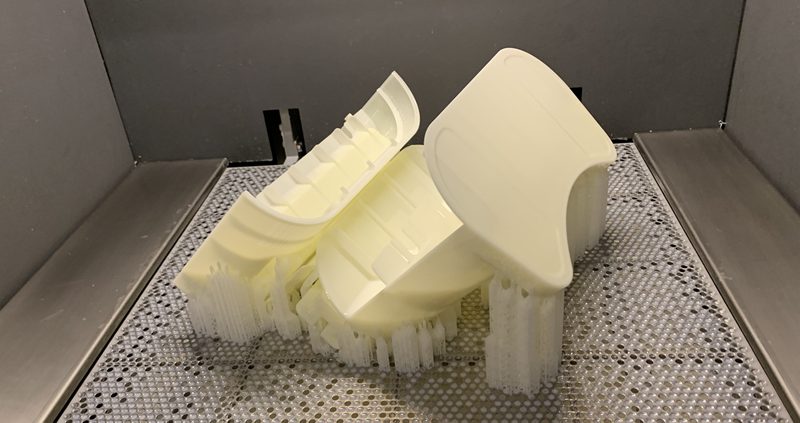

What are the advantages of SLS 3d printing process?

Compared with other rapid prototyping processes,the SLS 3d printing process for prototype production is unique in that it can directly produce metal prototypes.At the same time,this process also has the following advantages:

- The SLS 3d printing process is relatively simple,depending on the type and particle size of the material used,and the geometry and complexity of the prototype.The process can generally achieve a tolerance of ±0.15mm within the entire range of the prototype.When the powder particle size is less than 0.1mm,the accuracy of the prototype after molding can reach ±1%.

- There is no need to design a support structure,and the suspended layer that appears during the lamination process can be directly supported by the unsintered powder; and the material utilization rate is high,because there is no need to make a base support,the material utilization rate is high; the production cycle is short,and the application surface wide.

E-make company has 30 years of experience in custom-made production of rapid prototypes.The prototypes are exquisite in appearance,reliable in quality and delivered on time.If you want to customize the high-precision SLS 3d printing prototypes,E-make company is a good choice for you, and the quality rapid prototyping manufacturing service is waiting for you to experience.All information from customers was kept secret,we can sign an NDA with you before starting any work.

If you need any help,please feel free to contact us.