How to process polyethylene prototype

The polyethylene prototype is mainly processed by the method of silicone vacuum casting, and the main advantages are short processing time and low cost;In addition to making polyethylene prototypes, we can also make other materials, such as ABS, PP, PC, PMMA, POM, silicone, etc.Generally, a set of silicone molds can only be used for about 10 times and cannot be used. Reuse can cause deformation and large size errors.

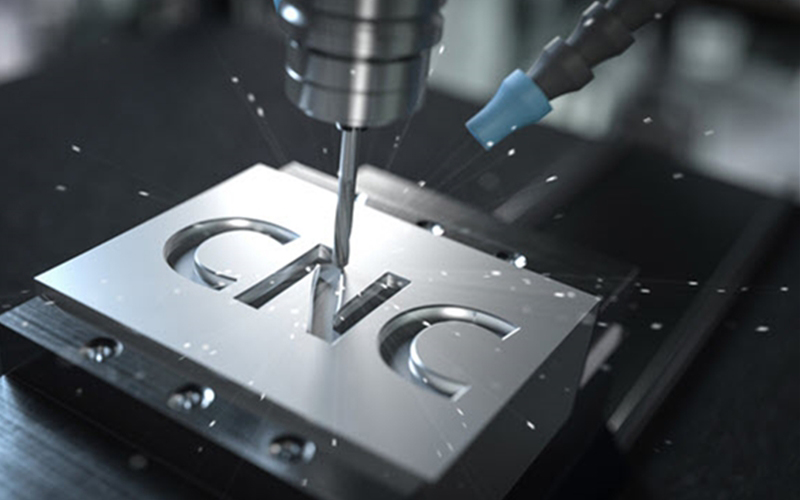

First of all, we need to make an original before making the silicone mold, which can be made by cnc machining or 3D printing.

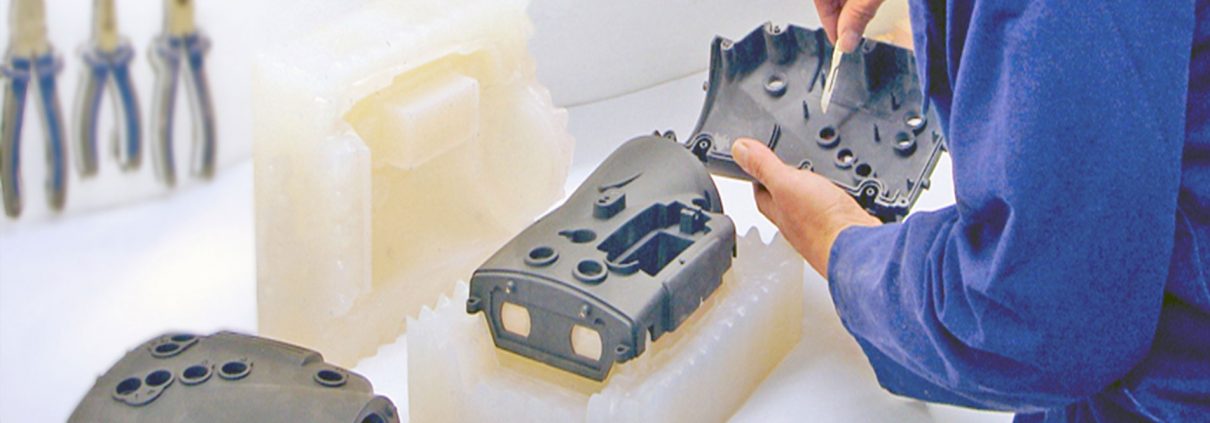

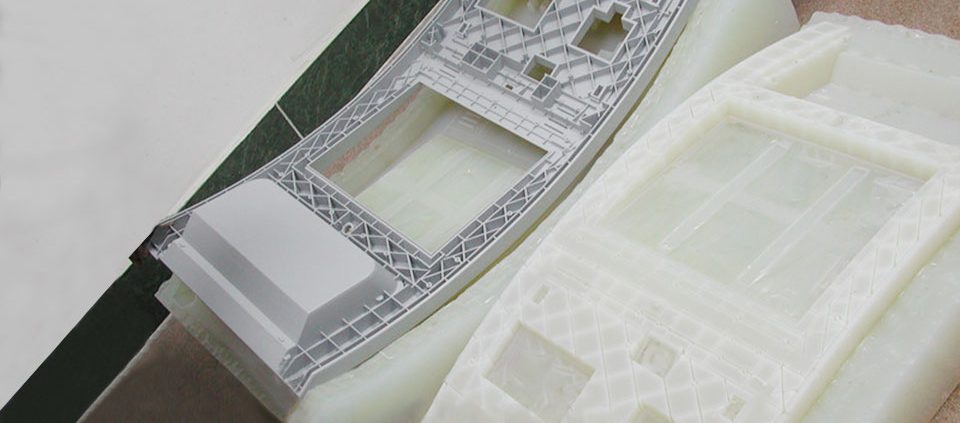

Then make the silicone mold: After the original is ready, start making the silicone mold. After the silicone mold is dried for eight hours, cut the silicone mold open, and then we can take out the prototype. At this time, the silicone mold is ready.

Final injection: Inject the liquid material into the silicone mold, and it will be completed after drying. The service life of the silicone mold is about 10 times.

The E-make team has more than 30 years of combined experience in prototype machining, CNC manufacturing, vacuum casting service.And has a high-level technological group of 25 peoples.The processing quality of the rapid manufacturing is stable, the processing precision is high, and the appearance is exquisite.

If you need any help,please feel free to contact us!